Experience & Vision

Top 10 Packaging and Machinery Innovations You Should Know?

In the fast-paced world of packaging and machinery, innovation plays a crucial role. The landscape is constantly shifting, pushing companies to embrace new technologies and methods. These advancements not only improve efficiency but also enhance sustainability in the industry.

Recent trends showcase exciting developments that transform how products are packaged and handled. For example, smart packaging solutions are gaining popularity. Such innovations monitor product freshness and provide real-time data to consumers. However, not every advancement meets expectations. Some new technologies can be costly and difficult to implement, leading to frustration among manufacturers.

Understanding these innovations is essential for staying competitive. Companies that adapt quickly will thrive, while others may struggle. The following exploration highlights ten key innovations in packaging and machinery. Each innovation presents both opportunities and challenges that deserve careful consideration.

Innovative Materials Transforming Packaging Solutions

Innovative materials are reshaping the packaging landscape. Biodegradable options are gaining traction. They minimize plastic waste and appeal to eco-conscious consumers. This shift is crucial as environmental concerns rise globally. Brands are experimenting with materials like hemp, mushroom mycelium, and cornstarch. These alternatives not only reduce environmental impact but also bring unique textures and appearances to packaging.

Another trend is the use of smart materials. Packaging that changes color or reveals tampering is becoming integral. Such innovations enhance safety and transparency, crucial for consumer trust. Yet, the technology behind these materials is still evolving. Challenges exist in cost and scalability, which can hinder widespread adoption. Improved performance and sustainability should remain priorities. The quest for packaging solutions continues to stir excitement and concern.

Consumer expectations are changing rapidly. They want packaging that not only protects but also enhances the product experience. Innovative materials certainly offer possibilities, but they also raise questions. Are these options truly sustainable in the long run? As industries adapt, continuous reflection on impacts is essential. The balance between innovation and responsible practices will define the future of packaging.

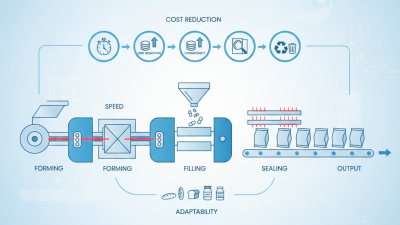

Automated Systems Enhancing Packaging Efficiency

Automated systems are revolutionizing the packaging industry. These systems significantly enhance efficiency and reduce costs. According to a recent report by MarketsandMarkets, the global automated packaging market is projected to reach $70 billion by 2025, growing at a CAGR of 7.4%. This growth highlights the demand for improved packaging solutions.

The integration of robotics in packaging lines boosts speed and accuracy. Robots can work alongside human operators, taking on repetitive tasks. This collaboration results in higher output. However, implementing these systems can be challenging. It requires proper training and workflow adjustments. Companies must ensure their workforce is ready for these changes.

Tips: Monitor the performance of automated systems regularly. Adjustments may be necessary to maintain efficiency. Also, consider gradual implementation to ease the transition.

Smart technologies like IoT and AI are changing how we package products. Intelligent systems can predict maintenance needs and optimize operations. However, over-reliance on technology can create vulnerabilities. Companies should balance automation with human expertise.

Investing in automation is not just about cutting costs. It’s about enhancing quality and sustainability too. Many organizations are still hesitant to adopt these systems fully. They may worry about upfront costs or losing jobs. Yet, the long-term benefits often outweigh these concerns.

Top 10 Packaging Innovations by Efficiency Gain

Sustainable Practices in Packaging Machinery Design

Sustainable practices in packaging machinery design are increasingly vital. Companies aim to reduce waste and energy consumption. Innovative machinery can make a big difference. For example, using biodegradable materials in machine parts can minimize environmental impact.

Tips: Choose energy-efficient machines. Look for those that reduce power use during production. Analyze materials carefully. Ensure they are sourced sustainably. Consider the entire lifecycle of packaging.

Investing in smarter technologies is crucial. Automated systems can optimize supply chain processes. They help to minimize excess production and waste. Yet, companies must be cautious. Not all new technologies are environmentally friendly. Some may require more resources than they save.

Tips: Regularly assess your machinery's performance. Is it meeting sustainability goals? Collaborate with vendors who prioritize eco-friendly practices. Share insights with team members about effective strategies. Open communication leads to better innovations.

Top 10 Packaging and Machinery Innovations You Should Know

| Innovation | Description | Sustainability Impact | Year Introduced |

|---|---|---|---|

| Biodegradable Films | Films made from organic materials that decompose naturally. | Reduces plastic waste and pollution. | 2022 |

| Smart Packaging | Packaging equipped with sensors to monitor freshness. | Minimizes food waste by indicating spoilage. | 2021 |

| Plant-Based Inks | Inks made from renewable resources for printing. | Decreases reliance on petroleum-based inks. | 2020 |

| Recyclable Packaging | Materials that can be easily recycled after use. | Supports circular economy and reduces landfill waste. | 2019 |

| Edible Packaging | Packaging that can be safely consumed. | Eliminates packaging waste entirely. | 2023 |

| Low Energy Machinery | Machines that consume less energy during operation. | Reduces carbon footprint of packaging processes. | 2021 |

| Water-Soluble Packaging | Packaging that dissolves in water, leaving no waste. | Eliminates plastic waste and enhances convenience. | 2022 |

| 3D-Printed Packaging | Customized packaging created using 3D printing technology. | Reduces material waste through precise manufacturing. | 2023 |

| Reclaimed Materials | Packaging made from previously used materials. | Supports recycling and resource reuse. | 2020 |

| Flexible Packaging | Adaptable packaging that reduces material use. | Significantly lowers the volume of waste generated. | 2019 |

Smart Technologies for Intelligent Packaging Solutions

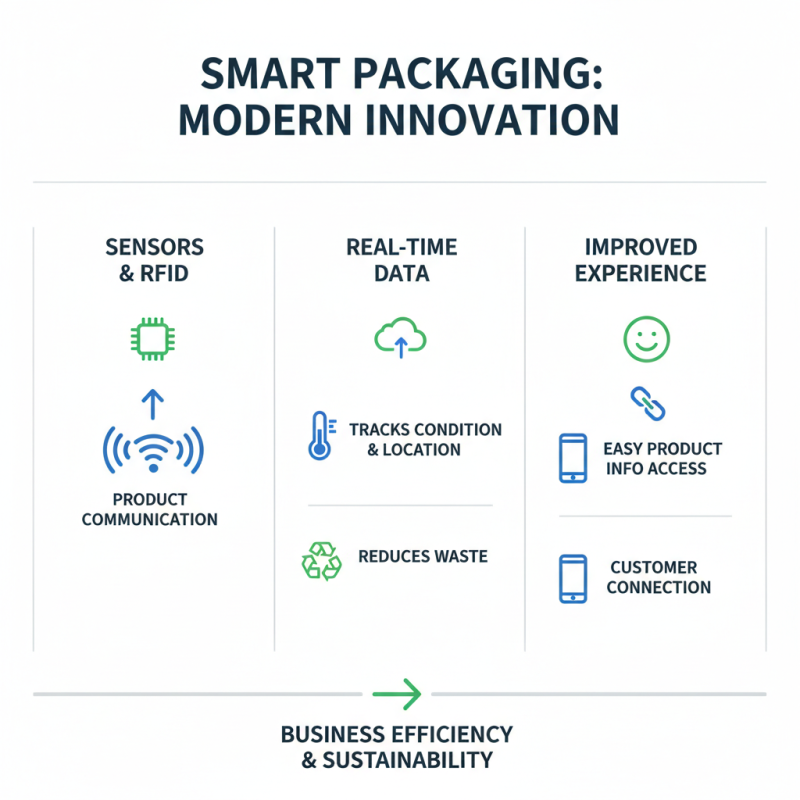

Smart packaging is at the heart of modern innovation. With technologies like sensors and RFID, products can communicate more. Real-time data helps track condition and location. This enables businesses to reduce waste significantly. It also improves customer experience. When consumers can access product information easily, they feel more connected.

Yet, challenges remain. Not all smart packaging integrates seamlessly with existing systems. Some companies struggle with data management. This can lead to inefficiencies and wasted resources. Packaging materials must be eco-friendly too. Consumers increasingly demand sustainable options. Striking a balance between technology and sustainability requires effort and creativity.

Intelligent packaging solutions can also enhance food safety. With temperature tracking, companies can ensure freshness. However, over-reliance on technology poses risks. Equipment failure or a lack of user understanding can result in losses. Innovating in packaging is exciting, but vigilance is essential to avoid pitfalls. Companies must reflect on their processes to truly benefit.

Next-Gen Printing Techniques Revolutionizing Packaging Aesthetics

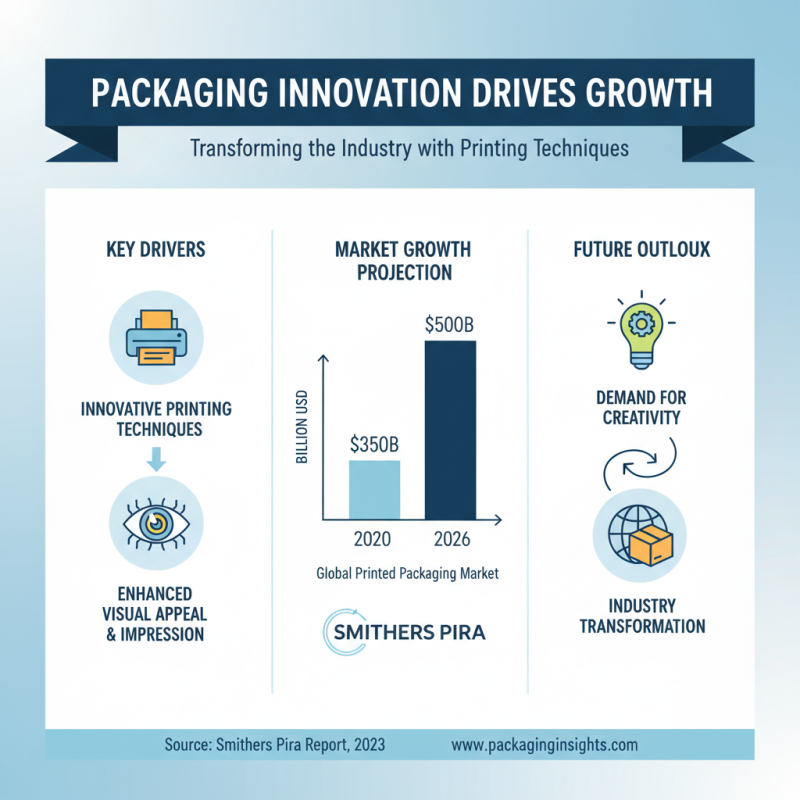

The packaging industry is on the brink of transformation, driven by innovative printing techniques. These advancements enhance visual appeal and leave lasting impressions. According to recent data from Smithers Pira, the global printed packaging market is projected to grow to $500 billion by 2026, fostering a demand for creativity.

Next-gen printing techniques, like digital inkjet and flexographic printing, offer unique benefits. They enable intricate designs on various materials, allowing brands to stand out. Brands are tapping into customization, as 70% of consumers favor personalized packaging. This shift not only boosts brand loyalty but also enhances the unboxing experience.

Tip: Experiment with diverse textures and colors to create a stunning look. Consider how your designs resonate emotionally with your audience. Strive to balance innovation and practicality. The pressure to innovate can lead to overwhelming choices, but careful, thoughtful designs make a powerful statement. Embrace trial and error. Some designs may not land as expected, which can guide future improvements.

Related Posts

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

How to Choose the Right Form Fill Packaging Machine for Your Business Needs

-

What is Packaging Equipment and How to Choose the Right One for Your Needs

-

2025 Guide: How to Choose the Right Packaging Machinery Equipment for Your Business

Products

Links

© Copyright 2025 | All Rights Reserved