Experience & Vision

Top 10 Cartoning Machines for Efficient Packaging Solutions

In today’s fast-paced manufacturing environment, efficient packaging solutions are paramount to maintaining competitive advantage. Cartoning machines play a crucial role in the packaging industry, automating the process of assembling, filling, and sealing cartons. According to a recent report by Smithers Pira, the global cartoning machines market is projected to grow at a CAGR of 4.8% over the next five years, driven by increasing demands for packaged goods and advancements in automation technology. As manufacturers pursue higher productivity and cost-effectiveness, the investment in state-of-the-art cartoning solutions becomes essential.

Expert in packaging technology, Dr. Emily Johnson, emphasizes the importance of modern cartoning machines in the industry: "Automated cartoning solutions not only enhance efficiency but also significantly reduce the risk of errors in packaging lines." This insight highlights the pivotal shift towards automation, where cartoning machines are not merely tools for packing but integral components of a streamlined production process. By investing in innovative cartoning technology, businesses can boost their operational efficiency and meet the evolving demands of consumers more effectively. In this article, we will explore the top 10 cartoning machines available today, showcasing how they can optimize packaging operations and contribute to overall business success.

Top 10 Cartoning Machines: An Overview of Industry Leading Options

In the fast-paced world of packaging, cartoning machines play a pivotal role in enhancing efficiency and automation. Recent reports from industry analysts indicate that the global cartoning machine market is projected to grow significantly, with an expected compound annual growth rate (CAGR) of approximately 6.2% over the next five years. This growth can be attributed to the increasing demand for packaged goods in sectors such as food and beverage, pharmaceuticals, and cosmetics. As companies seek to streamline their operations, investing in advanced cartoning technology becomes imperative.

Leading cartoning machines offer various features that cater to diverse packaging needs, such as speed, versatility, and user-friendly interfaces. For instance, many machines can handle multiple box sizes and formats, adapting swiftly to production requirements. Industry reports suggest that machines equipped with robotics and AI capabilities significantly reduce downtime and enhance overall productivity by up to 30%. As sustainability becomes a priority, the latest models also focus on eco-friendly packaging solutions, utilizing recyclable materials and reducing waste generated during the cartoning process. This alignment with environmental goals further emphasizes the importance of selecting the right cartoning machine for businesses aiming to optimize both efficiency and sustainability in their packaging strategies.

Key Features to Consider in Cartoning Machines for Optimal Performance

When selecting cartoning machines for efficient packaging solutions, several key features should be prioritized to ensure optimal performance. One of the most crucial aspects is the machine's speed and efficiency. According to a report by Smithers Pira, the global packaging machinery market is projected to grow at a CAGR of 3.7% from 2020 to 2025, underscoring the industry's demand for faster and more efficient packaging processes. Cartoning machines that can handle higher speeds while maintaining precision reduce overall production time and minimize material waste, which is essential for companies looking to enhance their productivity.

Another significant factor to consider is the machine's versatility in handling different types of products and cartons. Many modern cartoning machines are designed to accommodate a variety of product sizes and packaging styles without requiring extensive changeover time. A study by Freedonia Group indicates that flexible packaging is expected to account for a significant portion of the packaging market, increasing the need for adaptable machinery. Additionally, features such as user-friendly interfaces and automated settings allow operators to quickly adjust to different requirements, thereby improving workflow and efficiency on the production line.

Top 10 Cartoning Machines for Efficient Packaging Solutions

This chart illustrates the key features and performance metrics of the top 10 cartoning machines, including speed ( cartons per minute ), efficiency ( % efficiency ), and versatility ( number of packaging formats supported ).

Impact of Cartoning Machines on Packaging Efficiency and Cost Reduction

The implementation of cartoning machines has revolutionized the packaging industry, significantly enhancing efficiency and reducing costs. These machines streamline the process by automating the packaging of products into cartons, which minimizes the need for manual labor and decreases the time required for packaging. This automation not only accelerates production rates but also ensures consistency in packaging quality, reducing the risk of errors that can lead to costly waste.

Furthermore, the impact of cartoning machines extends beyond mere speed; they offer substantial cost savings. By integrating these machines into production lines, businesses can lower labor costs while simultaneously increasing output. The reduction in packaging materials due to precision cutting and folding technologies also contributes to lower overall operating expenses. As companies seek to optimize their supply chains, the efficiency brought by cartoning machines allows them to respond swiftly to market demands, ultimately enhancing their competitive edge in an ever-evolving marketplace.

Current Trends in Cartoning Technology: Innovations and Advancements

Recent advancements in cartoning technology have significantly transformed packaging practices across various industries, making them more efficient and adaptable to modern demands. One key trend is the integration of automation into cartoning machines, which streamlines the packaging process, reduces labor costs, and minimizes human error. Automated systems are now capable of adjusting to different box sizes and designs seamlessly, thus enhancing production flexibility. This shift not only improves productivity but also enables manufacturers to respond quickly to changing market needs.

Furthermore, sustainability is becoming a crucial focus in cartoning innovations. As environmental concerns rise, packaging solutions are increasingly being designed with eco-friendly materials and processes. Advances in technology allow for the use of recyclable or biodegradable materials in cartoning machinery, aligning with global sustainability goals. Manufacturers are also investing in energy-efficient systems that reduce waste and lower carbon footprints, demonstrating a commitment to responsible packaging solutions. These trends highlight the importance of continuous improvement in cartoning technology, ensuring that packaging remains not only effective but also environmentally conscious.

Top 10 Cartoning Machines for Efficient Packaging Solutions

| Model | Speed (cartons/min) | Dimensions (mm) | Weight (kg) | Key Features |

|---|---|---|---|---|

| Model A | 60 | 1500 x 800 x 1200 | 350 | Automatic, Compact Design |

| Model B | 80 | 1600 x 900 x 1300 | 450 | Energy Efficient, High Speed |

| Model C | 70 | 1700 x 850 x 1100 | 400 | User-Friendly, Fast Changeover |

| Model D | 90 | 1800 x 1000 x 1400 | 500 | Robust, Smart Control System |

| Model E | 75 | 1750 x 900 x 1150 | 480 | Flexible Setup, Safety Features |

| Model F | 65 | 1550 x 820 x 1250 | 360 | Compact, Low Noise |

| Model G | 85 | 1600 x 950 x 1300 | 490 | High Precision, Simple Maintenance |

| Model H | 92 | 1900 x 1020 x 1500 | 520 | Modular Design, Advanced Technology |

| Model I | 73 | 1650 x 910 x 1350 | 470 | User-Focused, Durable |

| Model J | 78 | 1720 x 880 x 1260 | 430 | Efficient, Multi-Format |

Comparison of Leading Brands: Performance Metrics and User Feedback

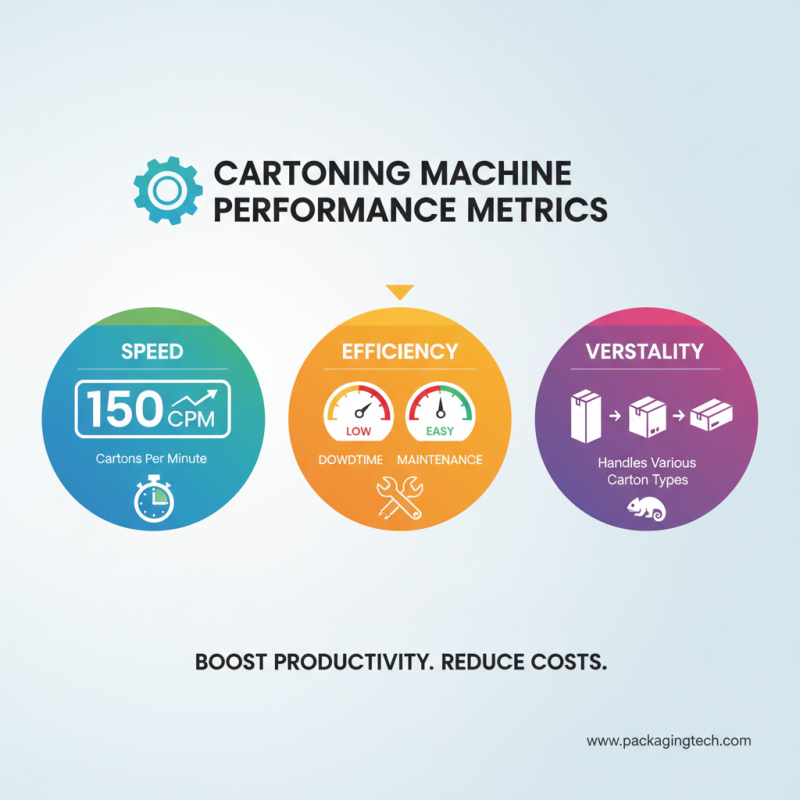

When it comes to selecting the ideal cartoning machine for packaging operations, performance metrics are crucial. Factors such as speed, efficiency, and the ability to handle various carton types are essential in determining a machine's effectiveness. Speed is often measured in cartons per minute (CPM), and machines boasting higher CPM ratings typically deliver better productivity. Additionally, efficiency can be assessed through metrics like downtime and ease of maintenance, which significantly impact overall operational costs.

User feedback plays an equally important role in the evaluation of cartoning machines. Operators often provide insights into usability, reliability, and customer service experiences. Positive user reviews frequently highlight the machine's ease of setup, programming flexibility, and robust construction, which can lead to longer-lasting performance. Conversely, negative feedback may draw attention to challenges such as complicated controls or lack of support from manufacturers. By comparing both quantitative performance metrics and qualitative user experiences, businesses can make well-informed decisions when investing in a cartoning machine tailored to their specific packaging needs.

Related Posts

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

-

What is a Filling Machine and How Does it Work in Various Industries

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Tips for Choosing the Best Overwrapping Machines for Your Business

Products

Links

© Copyright 2025 | All Rights Reserved