Experience & Vision

Top Bagging Machinery Equipment for Efficient Packaging Solutions?

In the rapidly evolving packaging industry, bagging machinery plays a pivotal role. Experts emphasize the importance of efficiency and precision. John McKinley, a leading authority in bagging technology, once stated, “The future of packaging lies in our ability to innovate bagging machinery.” His words resonate deeply as companies seek optimal solutions.

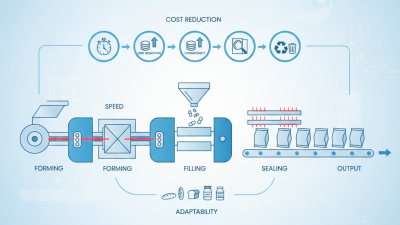

The demand for efficient packaging solutions drives advancements in bagging machinery. Manufacturers are increasingly focused on automation and speed. Each improvement reduces labor costs and enhances productivity. For instance, automated bagging systems can process thousands of bags per hour with minimal errors.

However, challenges remain. Not all businesses can invest in the latest technologies. Some companies struggle to integrate new machinery into existing lines. Reflecting on these issues is essential for future growth. The journey towards efficient bagging solutions demands continuous evaluation and adaptation. The potential is vast, and only time will tell how the industry will evolve.

Top Features to Consider When Choosing Bagging Machinery Equipment

When selecting bagging machinery equipment, several key features should influence your decision. Efficiency is paramount. Look for machines that optimize speed and reduce operational downtime. A reliable machine can significantly impact your overall productivity. However, not all machines perform equally well under various conditions.

The versatility of the equipment is another important aspect. It should handle different bag sizes and materials easily. Consider if the machinery can adapt to your changing needs. Flexibility will save you time and money in the long run.

Finally, focus on user-friendliness. Complex machines can be difficult to operate and maintain. Equipment that is intuitive will reduce training time and errors. However, simplicity doesn’t always mean effectiveness. Some simple systems may lack the necessary features. It's essential to find a balance between ease of use and functionality. Investing in quality bagging machinery is key to ensuring efficient packaging solutions.

Top Bagging Machinery Equipment Features

This bar chart illustrates the importance of various features to consider when choosing bagging machinery equipment. Speed is deemed the most critical factor, followed by accuracy and flexibility, whereas cost-effectiveness ranks lower.

Types of Bagging Machinery: A Comprehensive Overview

When it comes to packaging, various types of bagging machinery can significantly enhance efficiency. One common option is the vertical form fill seal (VFFS) machine. This equipment creates bags from a roll of film. It fills them with product and seals them in one continuous motion. This machinery is ideal for packaging snacks, powders, and granulated products. Operators often appreciate the speed and reduced labor costs.

Another option is the horizontal form fill seal (HFFS) machine. This type works well for items that require more space. It often uses pre-made pouches or bags. This can lead to better packaging aesthetics. However, some users find the setup time lengthy. Adjusting for different bag sizes can also be tricky. Regular maintenance is necessary to keep everything running smoothly.

Lastly, semi-automatic and automatic bagging machines serve niche markets. Semi-automatic machines are user-friendly. They require manual input, which some operators prefer. However, they might suffer from slower production speeds. Automatic machines, meanwhile, can process large quantities quickly. Despite their advantages, they can be costly and complex to operate. Finding the right balance between speed and cost-efficiency can be challenging.

Benefits of Automated Bagging Systems for Packaging Efficiency

Automated bagging systems are reshaping the packaging industry. These systems enhance efficiency by minimizing human error and speeding up processes. According to a report from the Packaging Machinery Manufacturers Institute (PMMI), automated systems can increase packaging speed by 30% on average. This is crucial as companies demand faster turnaround times.

These systems also offer greater accuracy. A study by PMMI highlighted that automated bagging reduces product waste by up to 20%. When products are packed accurately, companies save on costs. Less waste translates into better resource management. In an industry with profit margins tightening, this aspect is vital.

However, transitioning to automated systems isn't without challenges. Initial costs can be high, and not every facility may have the infrastructure to support such systems. Additionally, training staff to operate new technology can slow down immediate productivity. Reflecting on these factors is essential for companies considering automation. While the benefits are significant, understanding potential pitfalls is crucial for a smooth transition.

Top Bagging Machinery Equipment for Efficient Packaging Solutions

| Machine Type | Speed (Bags/min) | Bag Size (mm) | Forming Method | Material Compatibility | Automation Level |

|---|---|---|---|---|---|

| Vertical Form Fill Seal (VFFS) | 30 | 100-300 | Vertical | Plastics, Paper, Foil | Fully Automated |

| Horizontal Form Fill Seal (HFFS) | 45 | 150-400 | Horizontal | Plastics, Composite Films | Semi-Automated |

| Automatic Bagging Machine | 60 | 200-500 | Various | Paper, Biodegradable Materials | Fully Automated |

| Bagger with Weighing System | 50 | 100-1000 | Vertical/Horizontal | Granules, Powders | Fully Automated |

| Palletizing Bagging System | 20 | 250-800 | Vertical | Bulk Bags, Heavy Bags | Semi-Automated |

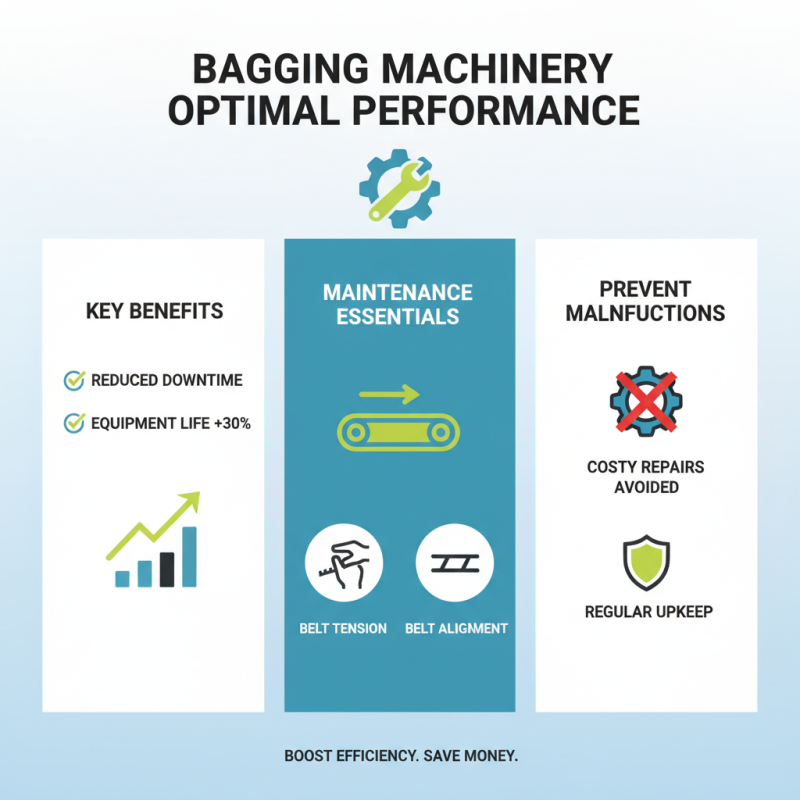

Maintenance Tips for Optimal Performance of Bagging Equipment

Maintaining bagging machinery is essential for optimal performance. Regular upkeep can significantly reduce downtime. Studies show that proper maintenance can boost equipment life by up to 30%. Basic checks should include examining belt tension and alignment. These simple actions help prevent costly malfunctions.

One key maintenance tip is to keep everything clean. Dust and debris can hinder operation. Many operators overlook this step, leading to unexpected breakdowns. Lubrication is another vital process. Employing the right grease at regular intervals can minimize friction. Interestingly, many equipment failures stem from inadequate lubrication.

Monitoring performance metrics is crucial. This means keeping an eye on speed, efficiency, and error rates. Implementing a routine logging system can highlight trends over time. It's easy to neglect this, but understanding patterns can facilitate better decision-making. Proper training for staff on these insights ensures everyone is on the same page.

Future Trends in Bagging Machinery Technology and Innovation

The bagging machinery industry is evolving rapidly, fueled by advancements in technology. The Global Bagging Machinery Market Report predicts a growth rate of over 6% annually until 2025. This growth is driven by rising demand for efficient and automated packaging solutions across various sectors.

Emerging trends indicate a shift towards digitalization and smart integration in machinery. Companies are increasingly adopting IoT-enabled equipment, allowing real-time monitoring and predictive maintenance. This innovation not only enhances operational efficiency but also minimizes downtime. A study by the Packaging Machinery Manufacturers Institute (PMMI) highlights that 50% of manufacturers are prioritizing automation to streamline processes and reduce labor costs.

However, challenges remain. The transition to smarter machinery can be costly and complex. Many companies struggle to integrate new technology with existing systems. Moreover, the shortage of skilled labor to operate advanced machinery is a pressing issue. As the industry moves forward, addressing these challenges will be crucial in shaping the future of bagging machinery.

Related Posts

-

How to Choose the Right Form Fill Packaging Machine for Your Business Needs

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

How to Choose the Best Pouching Machines for Your Packaging Needs

-

Top 5 Benefits of Using Fill and Seal Machines for Efficient Packaging

-

What is a Filling Machine and How Does it Work in Various Industries

Products

Links

© Copyright 2025 | All Rights Reserved