Experience & Vision

What is Packaging Equipment and How to Choose the Right One for Your Needs

In today's fast-paced manufacturing and distribution environments, the role of packaging equipment has transcended mere functionality to become a vital element in operational efficiency and product presentation. As businesses strive to meet consumer demands and optimize production processes, the selection of the right packaging equipment has become an essential consideration. With a plethora of options available, understanding the various types and features of packaging equipment can significantly impact the overall success of a product's journey from the production line to the end customer.

Choosing the appropriate packaging equipment goes beyond simply selecting a machine; it involves a thoughtful analysis of specific needs, including product characteristics, production volume, and desired packaging methods. Whether it's for food, pharmaceuticals, or consumer goods, the right equipment can enhance workflow, reduce waste, and improve safety standards. In this article, we will explore the fundamentals of packaging equipment, provide insights into the different types available, and offer guidance on how to make informed decisions tailored to your unique requirements. By understanding these key factors, businesses can empower themselves to enhance their packaging processes, ultimately leading to improved product integrity and customer satisfaction.

Understanding Packaging Equipment: Definition and Importance

Packaging equipment plays a crucial role in various industries, providing solutions that enhance product safety, quality, and shelf life. In a market that is projected to reach $50 billion by 2025, understanding the definition and importance of packaging equipment becomes essential for businesses seeking efficiency and competitiveness. This equipment includes machinery designed for processes such as filling, sealing, labeling, and wrapping, all of which streamline production while ensuring products are safely delivered to consumers. According to a report by Smithers Pira, investment in packaging technologies is expected to grow significantly, driven by the rise in e-commerce and the need for sustainable packaging solutions.

The significance of choosing the right packaging equipment cannot be overstated; it directly impacts production speed, cost-efficiency, and environmental sustainability. For instance, advanced automation technologies are enabling manufacturers to increase output while minimizing waste. A recent study highlighted that around 40% of production costs can be attributed to packaging processes, underscoring the need for businesses to invest wisely in equipment that meets their specific requirements. Furthermore, with the global shift towards eco-friendly practices, selecting equipment that supports sustainable packaging materials can enhance a company's market appeal and compliance with industry regulations, making it a fundamental aspect of modern business strategy.

Types of Packaging Equipment: An Overview of Options Available

Packaging equipment plays a crucial role in various industries, including food, pharmaceuticals, and consumer goods. Understanding the types of packaging equipment available can help businesses streamline their processes and improve efficiency. Key categories of packaging equipment include filling machines, labeling machines, and sealing machines. According to a report by MarketsandMarkets, the global packaging machinery market is projected to grow from $40.9 billion in 2020 to $55.3 billion by 2025, highlighting the increasing demand for automation and efficient packaging solutions.

Filling machines are essential for accurately dispensing products into containers, whether liquids, powders, or granules. Various technologies exist, such as volumetric, gravimetric, and piston filling, each suitable for different product types. Labeling machines, on the other hand, ensure that products are correctly identified and compliant with regulations. Advances in technology have led to high-speed labeling options that enhance productivity while significantly reducing labeling errors. Lastly, sealing machines are vital for ensuring product integrity and longevity, employing methods like heat sealing, vacuum sealing, and band sealing to meet specific packaging requirements.

Selecting the right type of packaging equipment depends on multiple factors, including production volume, product type, and budget constraints. Industry reports suggest that businesses should analyze their operational needs and production capabilities before investing in packaging solutions. With the right equipment, companies can effectively meet market demands and enhance product presentation, ultimately driving sales and customer satisfaction.

What is Packaging Equipment and How to Choose the Right One for Your Needs

| Type of Packaging Equipment | Description | Applications | Key Features |

|---|---|---|---|

| Filling Machines | Used to fill products into containers of various types. | Food and beverage, pharmaceuticals, chemicals. | Speed, accuracy, and flexibility in container sizes. |

| Labeling Machines | Automate the process of applying labels to products. | Consumer goods, e-commerce, retail. | Custom label sizes, precision application. |

| Sealing Machines | Used to seal packages and improve shelf life. | Food packaging, electronics, textiles. | Heat sealing, vacuum sealing, speeds. |

| Wrapping Machines | Wrap products for protection and presentation. | Shipping, retail, industrial goods. | Automatic vs manual wrapping, type of wrap material. |

| Cartoning Machines | Package products into cartons or boxes. | Cosmetics, food industry, consumer electronics. | Speed, carton design flexibility, automation level. |

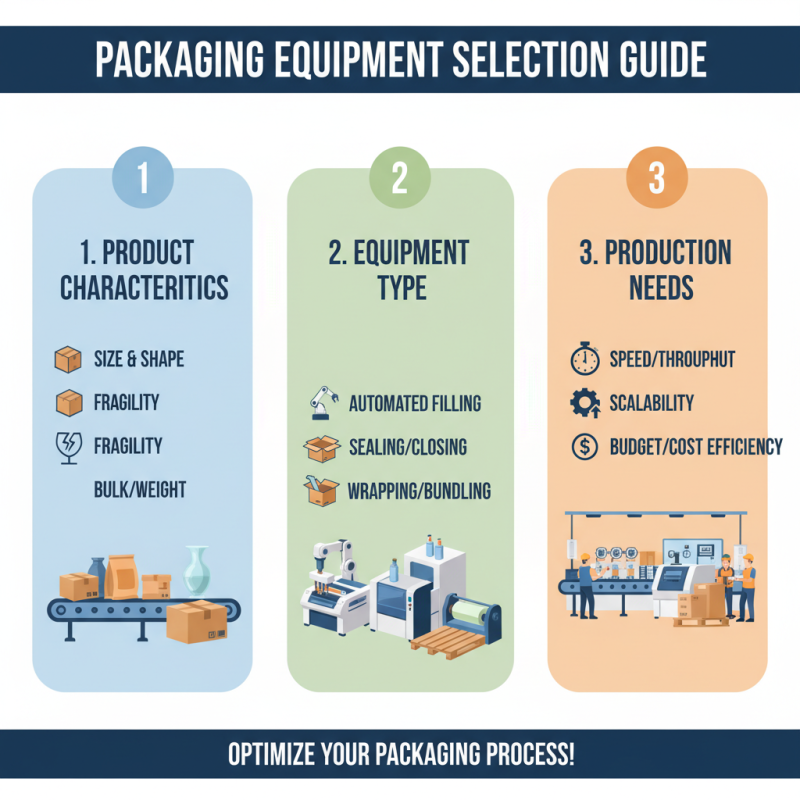

Factors to Consider When Choosing Packaging Equipment

When selecting packaging equipment, a few key factors must be taken into account to ensure that the chosen solution meets your production requirements efficiently. First and foremost, you should evaluate the nature of the product to be packaged. Consider aspects such as size, shape, and fragility, as these characteristics play a critical role in determining the type of equipment needed. For instance, delicate items may require specialized packing machinery that minimizes movement and damage, while bulkier products could necessitate heavy-duty machines built to handle larger loads.

Another important factor to weigh is the production volume. Understanding your current and projected packaging needs will help dictate the speed and automation level of the equipment. High-volume production might benefit from fully automated systems that enhance efficiency and reduce labor costs, whereas lower volumes could be better suited to semi-automated or manual equipment. Additionally, the flexibility of the packaging equipment should be considered, as having the ability to adapt to different product sizes or packaging types can greatly increase operational versatility and reduce long-term costs. Balancing these factors will lead to a more informed decision that aligns with your business’s unique packaging requirements.

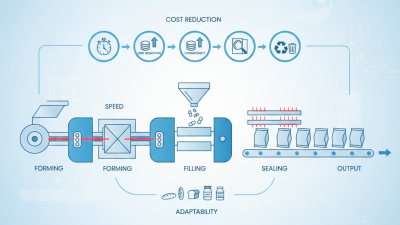

Evaluating Your Production Needs: Capacity and Efficiency Requirements

When evaluating packaging equipment, understanding your production needs is crucial. Capacity and efficiency requirements play a significant role in choosing the right machinery for your operations. According to a recent report by MarketsandMarkets, the global packaging equipment market is expected to grow from USD 45.45 billion in 2021 to USD 69.93 billion by 2026, reflecting an increasing demand for more efficient production systems across various industries. This growth underscores the need for businesses to scrutinize their requirements in terms of volume, speed, and type of packaging, ensuring that the equipment selected aligns with their operational goals.

Additionally, optimizing production efficiency requires a detailed analysis of current workflows and anticipated changes in demand. A study from Smithers Pira highlights that improving packaging line efficiency by just 15% can lead to significant cost reductions and higher profit margins. When evaluating equipment options, businesses should consider not only the upfront costs but also how each piece of machinery will integrate with existing systems. By assessing factors such as automation capabilities, ease of maintenance, and adaptability to different packaging formats, companies can make informed decisions that enhance their overall productivity while meeting evolving market demands.

Production Capacity and Efficiency Requirements

Maintenance and Support: Ensuring Longevity of Packaging Equipment

Maintenance and support are crucial considerations for ensuring the longevity and efficiency of packaging equipment. Regular maintenance not only prolongs the lifespan of machinery but also significantly reduces the risk of unexpected breakdowns, which can incur costly downtime. According to a report by the Machinery Maintenance Institute, proactive maintenance can increase equipment reliability by up to 30%, underscoring the importance of adopting a systematic approach to upkeep. Scheduled inspections and routine servicing can help identify potential issues before they escalate, allowing businesses to optimize their packaging processes and maintain production efficiency.

Furthermore, the support provided by equipment manufacturers can play an essential role in maximizing the effectiveness of packaging machinery. A survey conducted by the Packaging Equipment Manufacturers Institute revealed that companies investing in robust maintenance support services experience a 25% improvement in overall operational efficiency. When selecting packaging equipment, businesses should prioritize manufacturers that offer comprehensive maintenance programs and readily available customer support. This strategy reassures companies that, should challenges arise, expert assistance is just a call away, ultimately fostering a sustainable packaging operation that meets both quality and productivity demands.

Related Posts

-

What is a Horizontal Packaging Machine and How Does It Work?

-

How to Choose the Best Pouching Machines for Your Packaging Needs

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

Top 10 Tips for Choosing the Best Overwrapping Machines for Your Business

Products

Links

© Copyright 2025 | All Rights Reserved