Experience & Vision

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

In today's fast-paced manufacturing environment, the demand for efficient packaging solutions is more critical than ever. Overwrapping machines have become a vital component in maximizing productivity while ensuring product safety and integrity. As Mark Thompson, a leading expert in the packaging industry, states, "Overwrapping machines not only enhance product presentation but also provide a crucial barrier against environmental factors, ensuring that products reach consumers in pristine condition." This highlights the essential nature of overwrapping machines in modern packaging practices.

The innovation in overwrapping technology has transformed packaging workflows, enabling businesses to streamline operations and reduce waste. By utilizing these machines, companies can achieve high-speed packaging without compromising on quality. The ability to adapt overwrapping processes to various product types further emphasizes their significance in a diverse market landscape.

As manufacturers strive for operational excellence, understanding the benefits of overwrapping machines becomes imperative. With their capacity to improve efficiency and reduce costs, these machines stand at the forefront of packaging solutions, providing businesses with the competitive edge they need in today's economy.

Understanding Overwrapping Machines and Their Functionality

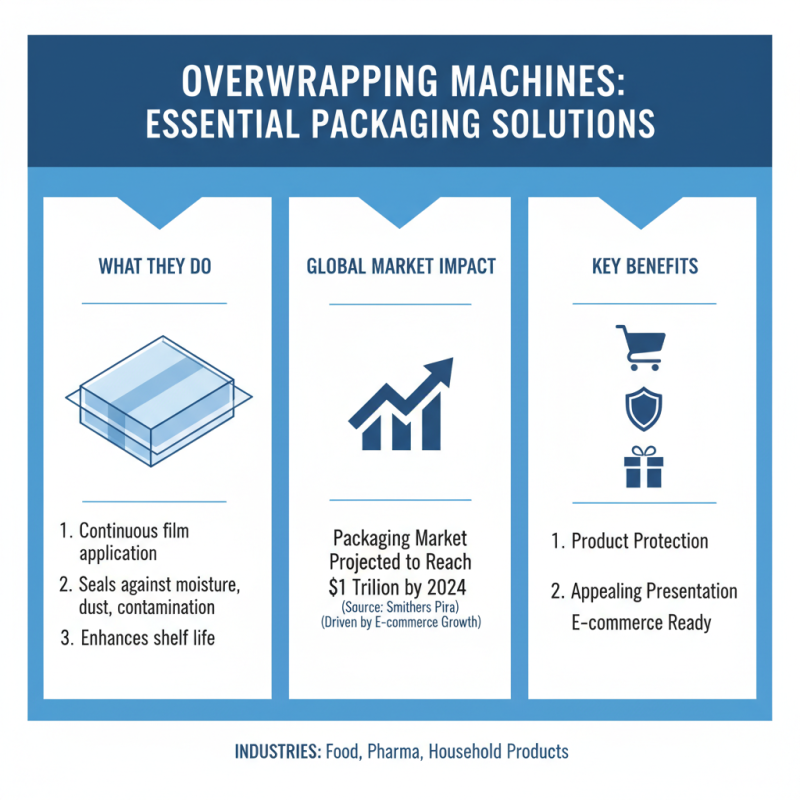

Overwrapping machines play a pivotal role in modern packaging solutions, providing a blend of efficiency and protection. These machines utilize a continuous film that wraps around products, sealing them from moisture, dust, and contamination. According to a report by Smithers Pira, the global packaging market is projected to reach $1 trillion by 2024, highlighting the increasing significance of efficient packaging methods. Overwrapping not only enhances product shelf life but also offers an appealing presentation that attracts consumers. With the rise of e-commerce and the subsequent need for quality packaging, overwrapping technologies have become essential in various industries, including food, pharmaceuticals, and household products.

In the realm of functionality, overwrapping machines are designed to maintain high speed and precision while minimizing material waste. They can adapt to diverse product shapes and sizes, making them versatile assets for manufacturers. Research indicates that automation in packaging can lead to a 30% reduction in labor costs, further validating the investment in such machinery. By utilizing advanced features like adjustable wrapping tension and automated feeding systems, companies can streamline their processes, leading to improved operational efficiency.

Tips: When selecting an overwrapping machine, consider factors such as production volume, product dimensions, and the type of materials you want to use. Regular maintenance of these machines can significantly extend their lifespan and performance. Additionally, training staff on proper operation techniques can enhance overall productivity and reduce the risk of downtime due to errors.

Key Benefits of Overwrapping in Packaging Efficiency

Overwrapping machines have become indispensable in modern packaging processes, providing significant enhancements in efficiency and sustainability. A recent report by Smithers Pira indicates that the global market for overwrapping machinery is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2025. This robust growth underscores the increasing recognition of overwrapping as a means to improve supply chain efficiency. By tightly encasing products in a protective film, these machines not only ensure product integrity but also allow for increased shelf life, demonstrating a dual advantage that appeals to both manufacturers and consumers.

One of the key benefits of overwrapping is its impact on packaging material usage. According to research from Freedonia Group, the implementation of overwrapping technology can lead to a reduction of up to 25% in material costs when compared to traditional packaging methods. This efficiency is primarily attributed to the precise application of materials, minimizing waste without compromising the protective qualities essential for products. Furthermore, overwrapping enables better branding opportunities, as the transparent film allows visibility of the product while maintaining a clean and professional appearance. This combination of cost-saving and aesthetic benefits makes overwrapping an essential feature in the drive for more effective packaging solutions.

Types of Overwrapping Machines in Modern Packaging

Overwrapping machines play a crucial role in modern packaging solutions by providing an efficient and secure method for wrapping products. These machines are designed to enhance the durability and presentation of various items, from consumer goods to pharmaceuticals. Among the different types of overwrapping machines, shrink wrappers are among the most popular. They utilize heat to shrink a plastic film tightly around the product, ensuring a snug fit that protects against moisture and contaminants while also offering an appealing visual display.

Another commonly used type is flow wrap machines, which operate with a continuous film that wraps around products, sealing them at both ends. This method is particularly effective for packaging items like snacks and bakery products, allowing for high-speed production and reduced material waste.

Additionally, there are case packers, which are usually integrated into larger packaging systems and serve to wrap entire boxes or cases of products for retail and shipping purposes. By understanding the various types of overwrapping machines available, businesses can select the most suitable solution to enhance their packaging efficiency, minimize waste, and meet specific product requirements.

Factors to Consider When Choosing Overwrapping Solutions

When considering overwrapping solutions for efficient packaging, several crucial factors come into play. First and foremost, the type of products to be wrapped significantly influences the machinery required. Different items, such as irregularly shaped goods or fragile products, demand specialized overwrapping techniques to ensure optimal protection and presentation. Understanding the specific requirements of your product line is essential for selecting the right overwrapping machine.

Another important consideration is the production speed and volume. Companies must evaluate their packaging needs based on current and projected output levels. High-speed overwrapping machines may be necessary for businesses with large volumes of products, while smaller operations might benefit from more compact, manual systems. Additionally, factors such as ease of operation, maintenance requirements, and the ability to adapt to changing packaging formats should also influence the decision-making process. Ultimately, selecting the right overwrapping solution will enhance efficiency, reduce waste, and improve the overall packaging quality.

Future Trends and Innovations in Overwrapping Technology

The future of overwrapping technology is shaped by an ongoing commitment to innovation, driven by the need for enhanced efficiency and sustainability in packaging solutions. Emerging trends include the utilization of smart sensors and automation, which enable machines to optimize production processes by monitoring real-time data. This not only increases throughput but also reduces waste during packaging, making it an environmentally friendly choice. Additionally, advancements in material science have led to the development of thinner, yet stronger, wrapping films that minimize plastic usage while maintaining product protection.

Tips for Implementing Overwrapping Innovations:

- Evaluate your current packaging processes to identify areas where automation could enhance efficiency. Investing in machinery that integrates with existing systems can ease the transition to more advanced overwrapping solutions.

- Stay abreast of new materials that offer better sustainability options. Transitioning to biodegradable films or recycled materials can improve your brand’s eco-friendliness while meeting consumer demand for sustainable products.

Furthermore, the incorporation of IoT technology into overwrapping machines is expected to revolutionize inventory management and supply chain logistics. With connected devices, companies can streamline operations by receiving immediate notifications about machine status, enabling proactive maintenance and reducing downtime. This trend not only enhances operational efficiency but also improves overall productivity, positioning manufacturers to better meet the fast-changing demands of the marketplace.

Products

Links

© Copyright 2025 | All Rights Reserved