Experience & Vision

What is a Horizontal Packaging Machine and How Does It Work?

In the dynamic landscape of modern packaging, the horizontal packaging machine has emerged as a pivotal player, significantly enhancing efficiency and productivity across various industries. According to a recent report by Smithers Pira, the global packaging machinery market is projected to grow at a CAGR of 5.8% from 2021 to 2026, with horizontal packaging machines accounting for a substantial share due to their versatility and speed. This innovative technology caters to a wide range of applications, making it an essential asset for manufacturers eager to meet consumer demands for fast and efficient packaging solutions.

Industry expert Dr. Ellen Thompson, a leading authority on packaging technologies, emphasizes the importance of horizontal packaging machines by stating, "The versatility and efficiency of horizontal packaging systems not only streamline production lines but also contribute to significant cost savings." As the industry continues to evolve, the integration of automation and smart technology within horizontal packaging machines promises to further enhance their performance, enabling businesses to maintain a competitive edge in an increasingly demanding market.

Understanding the functionality of a horizontal packaging machine is crucial for manufacturers looking to optimize their packaging processes. By exploring its mechanisms and advantages, businesses can better navigate the complexities of modern packaging requirements while reaping the benefits of increased output and minimized waste.

What is a Horizontal Packaging Machine?

A horizontal packaging machine is a versatile piece of equipment designed to package various products in a horizontal position. Typically used in industries such as food, pharmaceuticals, and consumer goods, this machine helps streamline the packaging process by efficiently wrapping items with film, cardboards, or other materials.

The design allows for fast and efficient handling, reducing labor costs and enhancing productivity. Items are placed in a horizontal orientation, enabling the machine to wrap them tightly, ensuring secure packaging for shipping or storage.

When using a horizontal packaging machine, it's essential to consider the size and weight of the products you plan to package. Ensure the machine settings are adjusted accordingly for optimal performance. Regular maintenance is also crucial; keep the equipment clean and check for any wear and tear to avoid unexpected breakdowns.

Tips: To maximize efficiency, conduct regular training sessions for your staff on machine operation and safety protocols. This minimizes errors and enhances productivity. Additionally, testing new materials for packaging can lead to cost savings while ensuring the quality necessary for your products.

Key Components of Horizontal Packaging Machines

Horizontal packaging machines are widely used in various industries for their efficiency in packaging products. The key components of these machines play a significant role in their functionality and performance. One of the primary components is the film feed system, which provides the packaging material. This system is designed to ensure a consistent supply of film, allowing for uninterrupted packaging processes. A precise film tension mechanism is also integral, as it helps maintain the right amount of pressure during the packaging cycle, which is crucial for achieving tight seals.

Another vital component is the forming and sealing station. This part is responsible for shaping the packaging pouch and sealing it securely. It often utilizes heat sealing technology to create strong, tamper-evident seals, which are essential for maintaining product integrity. Additionally, the control system of the horizontal packaging machine coordinates the operation of all components, allowing for easy adjustments and programmable settings. This enhances the machine's adaptability to various packaging formats and speeds, catering to different production needs. Together, these components work harmoniously to deliver efficient and reliable packaging solutions.

What is a Horizontal Packaging Machine and How Does It Work? - Key Components of Horizontal Packaging Machines

| Component | Description | Function |

|---|---|---|

| Film Roller | Holds the packaging film before it is shaped and sealed. | Provides the material needed for packaging products. |

| Sealing Mechanism | Creates seals around the package using heat or pressure. | Ensures product freshness and prevents contamination. |

| Filling System | Dispenses the product into the packaging. | Automatically fills packages with the correct amount of product. |

| Control Panel | User interface for operating and monitoring the machine. | Allows operators to set parameters and control the packaging process. |

| Conveyor System | Transports products through the packaging line. | Facilitates smooth movement and alignment of products for packaging. |

The Working Mechanism of Horizontal Packaging Machines

Horizontal packaging machines are essential in various industries for efficient product packaging. They operate by placing products in flexible film, which is then folded and sealed to create a tightly wrapped package. The mechanism typically includes feeding, forming, filling, and sealing stations, allowing for continuous operation and high-speed production. According to a report by MarketsandMarkets, the global horizontal packaging machinery market is projected to reach USD 5.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.5% from 2020 to 2025.

The working mechanism of horizontal packaging machines begins with the input of flat film rolls, which are unwound and guided into a series of forming molds. As the film moves, it is shaped into a tube while simultaneously being filled with the product. The sealing process follows, where heat or pressure is applied to join the film edges, creating a secure package. This streamlined process reduces manual labor and minimizes packaging waste, making it a preferred choice in industries such as food, pharmaceuticals, and cosmetics. Industry reports indicate that up to 30% of time and material can be saved compared to traditional packaging methods, further driving the adoption of these machines across various sectors.

Common Applications and Industries Using Horizontal Packaging

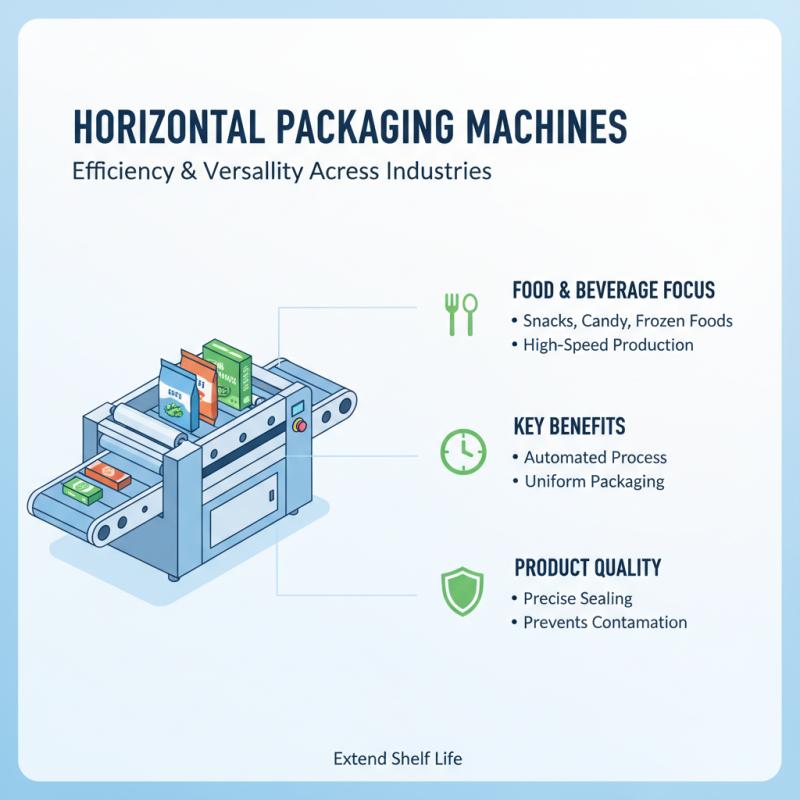

Horizontal packaging machines are widely utilized across various industries due to their efficiency and versatility. These machines are particularly common in the food and beverage sector, where they package items such as snacks, candy bars, and frozen foods. The automated process allows for high-speed production and ensures uniform packaging, which is crucial for maintaining product quality and extending shelf life. Additionally, the precise sealing capabilities of horizontal packaging machines prevent contamination, making them ideal for the food market.

Apart from food applications, horizontal packaging machines are also used extensively in pharmaceuticals and personal care products. In the pharmaceutical industry, they provide an efficient means of packaging tablets, capsules, and other medical supplies, ensuring that they are securely sealed to meet safety standards. Similarly, in personal care, products like cosmetics and hygiene items benefit from the sleek and professional appearance achieved through horizontal packaging. This technology adapts to various materials and sizes, making it a preferred choice across multiple applications, ultimately enhancing efficiency and product presentation in competitive markets.

Advantages of Using Horizontal Packaging Machines in Production

Horizontal packaging machines play a crucial role in modern production lines, offering a multitude of advantages that enhance operational efficiency. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), the global market for packaging machinery is projected to reach $45 billion by 2026, driven largely by the demand for horizontal packaging systems in industries such as food and beverages, pharmaceuticals, and personal care products. These machines are known for their versatility in handling various products, from granules to liquids, and their ability to achieve high-speed packaging while maintaining product integrity.

One of the key benefits of horizontal packaging machines is their efficiency in space utilization. These machines require less vertical space compared to vertical systems, making them ideal for facilities with height limitations. Additionally, horizontal machines can operate at remarkable speeds, often exceeding 120 packages per minute, significantly boosting productivity. A study by Freedonia Group indicates that automated packaging solutions, including horizontal machines, can reduce labor costs by up to 20%, allowing manufacturers to allocate resources more strategically. Furthermore, the ability to customize packaging formats enhances flexibility, enabling companies to quickly adapt to market demands and consumer preferences, thus ensuring a competitive edge in the fast-paced packaging landscape.

Products

Links

© Copyright 2025 | All Rights Reserved