Experience & Vision

What is a Form Fill Packaging Machine and How Does It Work for Your Business

In the rapidly evolving landscape of the packaging industry, the form fill packaging machine has emerged as a vital asset for businesses seeking efficiency and reliability. According to a report by Grand View Research, the global packaging machinery market is projected to reach USD 50 billion by 2024, highlighting the growing importance of automated solutions like form fill packaging machines in meeting consumer demand. These machines streamline the packaging process by creating a package, filling it with products, and sealing it in one continuous operation, thus significantly reducing labor costs and increasing production speed.

Industry expert Dr. Linda Harmon, a leading analyst in packaging technology, states, "Investing in a form fill packaging machine can revolutionize a company’s production line, enhancing not only efficiency but also product consistency." This statement underlines the transformative potential that these machines hold for businesses across various sectors, particularly in food, pharmaceuticals, and consumer goods. By leveraging advanced technology, companies can ensure precise filling and sealing, resulting in improved quality control and reduced waste.

As businesses continue to seek innovative solutions for efficient operations, understanding the mechanics and advantages of form fill packaging machines becomes crucial. With their ability to adapt to various product types and packaging formats, these machines are set to play a pivotal role in shaping the future of packaging.

What is a Form Fill Packaging Machine?

A form fill packaging machine is a sophisticated piece of equipment used in various industries to automate the process of packaging products. At its core, this machine is designed to create packages from flat rollstock films, fill them with product, and then seal them for distribution. The process typically begins with the machine unwinding a roll of flexible packaging material, which is then fed into a forming section where it is shaped into a pouch or bag. Once the desired form is achieved, the machine fills the package with the product, be it food, pharmaceuticals, or other consumer goods.

The functionality of a form fill packaging machine is not only efficient but also versatile. These machines can handle a wide range of product types and sizes, making them ideal for businesses that require customized packaging solutions. The sealing mechanisms can vary, allowing for different types of package integrity to suit the product's needs, whether it's vacuum-sealed for freshness or simply heat-sealed for convenience. By incorporating advanced controls and automation, businesses can streamline their packaging processes, reduce labor costs, and improve overall production efficiency, ensuring that their products reach consumers in optimal condition.

Form Fill Packaging Machine Efficiency Analysis

Key Components of Form Fill Packaging Machines

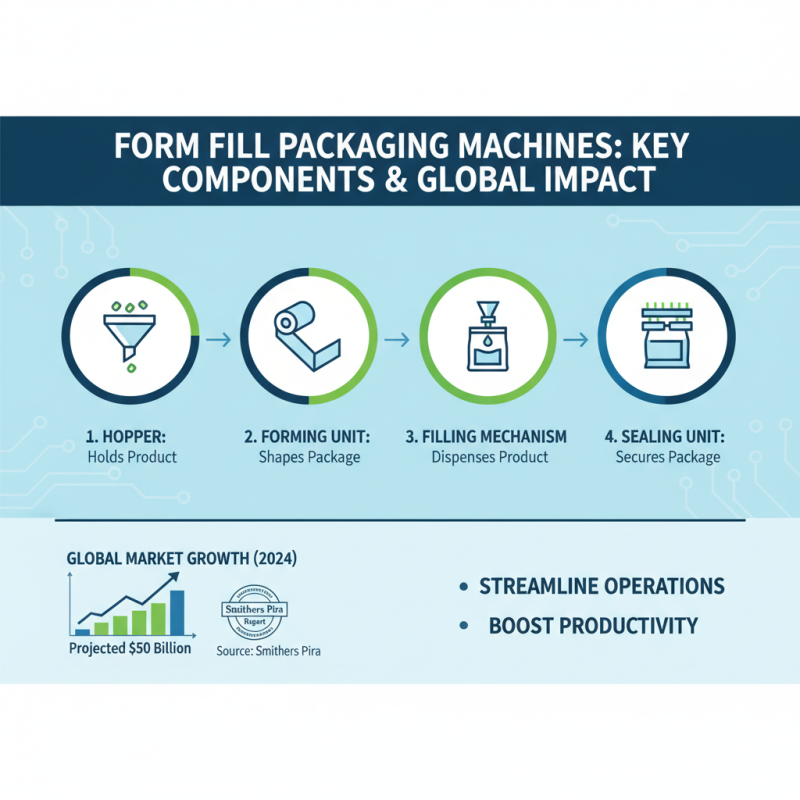

Form Fill Packaging Machines are crucial in the packaging industry, particularly for businesses looking to streamline their operations and enhance productivity. Understanding the key components of these machines is essential for optimizing your packaging process. The primary components include the hopper, which holds the product, the forming unit that shapes the packaging material, the filling mechanism, and the sealing unit that secures the packaged goods. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach around $50 billion by 2024, highlighting the growing significance of automation in packaging.

When choosing a Form Fill Packaging Machine, it’s important to consider the machine’s speed and efficiency. High-quality machines can operate at speeds of over 100 packages per minute, which can significantly increase output and reduce labor costs. Moreover, select machines that offer flexibility for various package types and sizes—this adaptability can help businesses cater to diverse product offerings without needing multiple machines, thus saving on capital expenditure.

Tips: Always assess the machine’s ease of use and maintenance requirements. Investing in a machine that requires minimal downtime for adjustments and repairs can further enhance productivity. Additionally, consider incorporating automation features such as sensors that monitor fill levels and sealing integrity, which can ensure consistent quality and reduce waste, ultimately benefiting your bottom line.

How Form Fill Packaging Machines Operate

Form fill packaging machines are essential tools in the packaging industry, designed to automate the process of filling and sealing various products into containers. These machines operate by first forming a pouch or container from a flat roll of film or material. Once the desired shape is created, the machine then precisely fills the container with the product, ensuring the correct amount is dispensed. The filling process can be tailored to accommodate a variety of products, whether they are liquid, powder, granules, or solid items, making them highly versatile for different business needs.

Once the filling is complete, the machine typically seals the container using heat, adhesive, or other sealing technologies to maintain product freshness and prevent leakage. The operation can be further enhanced with integrated features such as labeling, coding, and quality control functions that ensure each package meets the required standards. By incorporating these machines into production lines, businesses can significantly increase efficiency, reduce labor costs, and enhance packaging consistency, ultimately leading to improved customer satisfaction and enhanced product shelf life.

Benefits of Using Form Fill Packaging Machines in Business

Form fill packaging machines have become increasingly popular in various industries due to their efficiency and versatility in packaging processes. One of the primary benefits of using these machines is the significant reduction in labor costs. By automating the packaging process, businesses can streamline operations and allocate human resources to more critical tasks, allowing for improved productivity. Additionally, these machines can operate continuously, which allows companies to meet high demand without compromising on speed or quality.

Another advantage of form fill packaging machines is the enhancement of product consistency and quality. These machines are designed to create precise packages that not only protect the product but also ensure uniformity. This consistency is vital for maintaining brand image and consumer trust. Moreover, form fill machines offer flexibility in packaging various products, whether solids, liquids, or powders. This adaptability makes them ideal for diverse industries, from food and beverage to pharmaceuticals, as they can cater to specific packaging needs without extensive reconfiguration.

Selecting the Right Form Fill Packaging Machine for Your Needs

When selecting the right form fill packaging machine for your business, it's crucial to start with a clear understanding of your specific needs and the type of products you plan to package. According to a report by Smithers Pira, the global market for flexible packaging is projected to reach $248 billion by 2024, highlighting the growing importance of efficient and cost-effective packaging solutions. Factors such as the nature of the product, production speed requirements, and desired level of automation should all guide your decision-making process.

Additionally, consider the machine's compatibility with various types of materials. Many companies are opting for machines that can handle both plastic and biodegradable materials, aligning with the trend of sustainability in packaging. It's estimated that around 49% of packaged goods now utilize some form of sustainable packaging, as consumers increasingly favor eco-friendly options. This aligns with the capabilities of modern form fill machines, which can often be adjusted to work with different substrates, providing flexibility for businesses.

Tips: When evaluating different options, prioritize machines that offer easy setup and maintenance. This can significantly reduce downtime during production, ensuring your operations run smoothly. Additionally, consult with industry experts or conduct site visits to understand how different machines perform in real-world settings, ultimately enabling you to make a more informed choice.

Related Posts

-

What is a Filling Machine and How Does it Work in Various Industries

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Tips for Choosing the Best Overwrapping Machines for Your Business

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

Products

Links

© Copyright 2025 | All Rights Reserved