Experience & Vision

What is a Filling Machine and How Does it Work in Various Industries

Filling machines play a crucial role in the manufacturing and packaging sectors, providing efficiency and precision in the filling process across various industries. These machines are designed to automate the task of dispensing liquids, powders, and granular products into containers of different shapes and sizes, thereby significantly improving production speed and reducing human error. As industries seek to optimize their operations and meet market demands, the utilization of filling machines has become increasingly prevalent, making them an essential component in sectors ranging from food and beverage to pharmaceuticals and cosmetics.

The importance of filling machines extends beyond mere efficiency. They contribute to product consistency and quality control, ensuring that each container is filled to the specified level, which is vital for both regulatory compliance and customer satisfaction. With advancements in technology, modern filling machines are equipped with sophisticated features such as customizable filling volumes, automated cleaning systems, and integration capabilities with other machinery, allowing for seamless operation. This adaptability makes them indispensable in a landscape where precision and innovation are paramount for businesses striving to maintain a competitive edge. Overall, understanding how filling machines work and their applications across different industries can provide valuable insights into their operational significance and impact on productivity.

What is a Filling Machine?

A filling machine is a crucial piece of equipment used in various industries to dispense precise amounts of products into containers. This technology is instrumental in sectors such as food and beverage, pharmaceuticals, cosmetics, and chemicals, where accuracy and efficiency are paramount. According to a recent report by Grand View Research, the global filling machine market was valued at approximately $4.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of around 5.2% from 2023 to 2030. This growth underscores the escalating demand for automation and precision in manufacturing processes across multiple sectors.

Filling machines operate through various mechanisms, including volumetric, gravimetric, and pump-based systems. These machines ensure that each container receives the correct volume of product, minimizing waste and enhancing productivity. For example, volumetric filling machines are commonly used in the beverage industry, where they can fill thousands of bottles per hour with consistency. Statistics from the Packaging Machinery Manufacturers Institute indicate that filling machines account for nearly 25% of the total packaging machinery market, highlighting their importance in facilitating streamlined operations and maintaining quality standards in production.

Types of Filling Machines Used in Different Industries

Filling machines play a crucial role across various industries by automating the process of filling products into containers. These machines can be categorized into several types based on the specific requirements of different sectors. For example, volumetric filling machines are prevalent in the beverage industry, where they ensure precise measurement and filling of liquids. According to a recent report by MarketsandMarkets, the liquid filling machine market is expected to reach USD 6.79 billion by 2026, driven primarily by the demand for high efficiency and reduced operational costs in beverage production.

In contrast, semiautomatic and automatic pneumatic filling machines are commonly utilized in the pharmaceutical industry. These machines are designed to handle viscous liquids and provide high precision, thus ensuring compliance with stringent health regulations. The pharmaceutical sector accounted for approximately 25% of the overall filling machines market share in 2022, as highlighted by a study from Research and Markets, emphasizing the industry's reliance on advanced filling technology to enhance productivity and maintain quality standards.

Moreover, the food industry relies heavily on inline filling machines, which are essential for maintaining product integrity and minimizing contamination risks. According to industry insights from Grand View Research, the food filling machines segment is projected to grow at a CAGR of 8.5% from 2023 to 2030, largely due to increasing consumer demand for packaged foods. This diverse range of filling machines underscores their importance in facilitating efficient production across different sectors while meeting specific regulatory and operational challenges.

The Working Principle of Filling Machines Explained

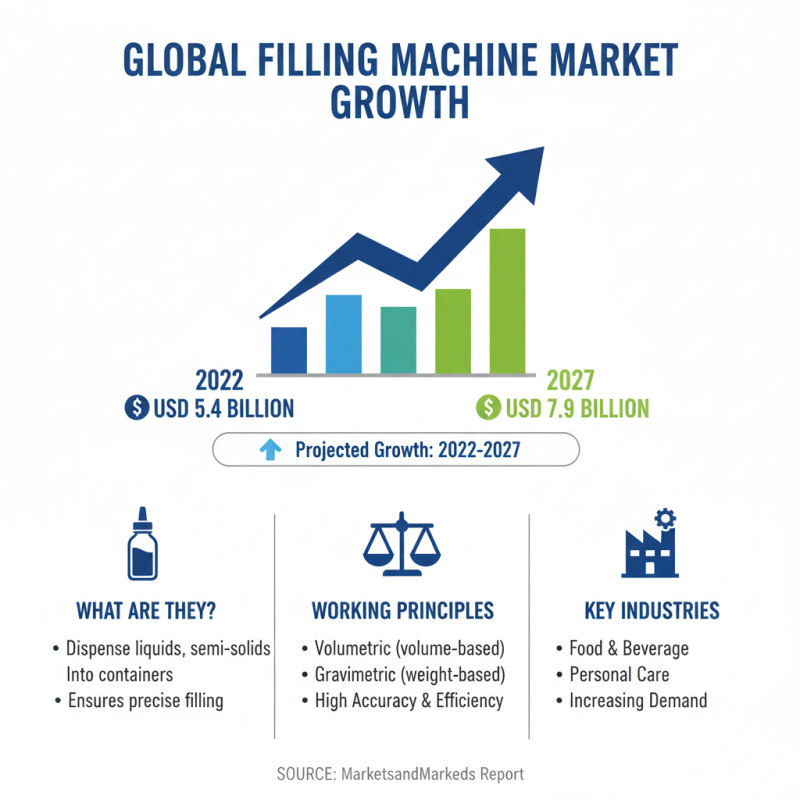

Filling machines are vital components in numerous manufacturing sectors, responsible for the precise dispensing of liquids, powders, and semi-solids into containers. The working principle of these machines can vary based on the product and intended application. Generally, filling machines operate on the mechanism of volumetric or gravimetric filling, both of which ensure high accuracy and efficiency. According to a report by MarketsandMarkets, the global filling machine market is projected to grow from USD 5.4 billion in 2022 to USD 7.9 billion by 2027, reflecting the increasing demand across food and beverage, pharmaceuticals, and personal care industries.

The volumetric filling machines function by measuring the volume of product to be dispensed, which can be done using pistons, pumps, or gravity. This method is particularly common in the food and beverage industry, where consistent portion control is essential for quality assurance. On the other hand, gravimetric filling machines rely on weight measurements to accurately fill containers, making them ideal for products like powders or granules in industries such as pharmaceutical and chemicals. These machines are not only efficient but also enhance production speed, which, according to a study by Grand View Research, can lead to a reduction in labor costs by up to 30% in high-volume manufacturing environments.

As filling technology advances, the integration of automation and digital monitoring systems is becoming increasingly prevalent. These innovations enable real-time tracking and adjustments during the filling process, ensuring enhanced precision and reduced wastage. A report by Allied Market Research indicates that automated filling systems are expected to witness significant growth, contributing to increased efficiency and safety in the workplace, which is crucial in industries where hygiene and contamination prevention are paramount.

Applications of Filling Machines in Food and Beverage Industry

Filling machines play a crucial role in the food and beverage industry by ensuring efficiency and consistency in the packaging process. These machines are designed to automate the filling of various product types, such as liquids, solids, and powders, directly into containers like bottles, jars, or pouches. Their applications range from filling beverages like juices and soft drinks to packaging sauces, dressings, and even ready-to-eat meals. The precision and speed with which filling machines operate contribute significantly to meeting the high demands of modern consumers while maintaining product quality.

In addition to enhancing productivity, filling machines help in minimizing waste and ensuring hygiene, which are vital factors in the food and beverage sector. Many filling machines are equipped with advanced technology that allows for accurate measurement, reducing product spillage and ensuring each container is filled to the correct capacity. They can also be designed to accommodate various types of packaging and handle different viscosities, making them versatile tools in production lines. By utilizing automated filling processes, companies can not only speed up their operation but also maintain high standards of safety and consistency in their product offerings, ultimately leading to improved customer satisfaction.

What is a Filling Machine and How Does it Work in Various Industries - Applications of Filling Machines in Food and Beverage Industry

| Application Area | Machine Type | Common Products | Filling Mechanism |

|---|---|---|---|

| Beverage Industry | Gravity Filling Machine | Juices, Soft drinks | Uses gravity to fill |

| Dairy Industry | Piston Filler | Milk, Yogurt | Uses a piston to inject product |

| Sauces and Condiments | Vacuum Filling Machine | Ketchup, Mustard | Creates a vacuum to fill |

| Bakeries | Net Weight Filler | Batter, Dough | Fills by weight measurement |

| Oils and Liquids | Electronic Filling Machine | Cooking oil, Motor oil | Uses electronic control for precision |

Innovations and Trends in Filling Machine Technology

Innovations in filling machine technology are transforming various industries, particularly food and beverage, pharmaceuticals, and cosmetics. The market for filling machines is forecasted to grow at a compound annual growth rate (CAGR) of around $6 billion by the end of 2026, according to industry reports. This growth can be attributed largely to advancements in automation and smart technology, which enhance precision and efficiency in the filling process. For instance, the integration of artificial intelligence enables real-time monitoring and adjustments to optimize production lines and reduce waste.

In recent years, there has been a significant trend toward the use of sustainable materials and eco-friendly practices in the manufacturing of filling machines. Studies indicate that over 30% of industry players are investing in technologies that allow for reduced energy consumption and recyclable materials. Furthermore, the development of modular filling systems allows for greater flexibility in production, enabling manufacturers to easily switch between different products and packaging formats without significant downtime. This adaptability is crucial in responding to changing consumer demands and regulatory requirements in various markets. As the industry continues to evolve, the importance of innovative filling machine technology in driving operational efficiency and sustainability cannot be overstated.

Products

Links

© Copyright 2025 | All Rights Reserved