Experience & Vision

10 Essential Tips for Operating a Roll Stock Machine Effectively?

In the realm of manufacturing, the roll stock machine plays a critical role in streamlining processes. According to industry expert, John Smith, “The efficiency of a roll stock machine can make or break production timelines.” His insight highlights the importance of effective operation.

Operating a roll stock machine requires skill and awareness. Operators must understand each setting and its impact on the final product. It's easy to overlook minor adjustments that can lead to significant issues. For instance, incorrect tension can cause defects, which affects product quality.

Moreover, monitoring performance is crucial. It allows for timely interventions. Continuous training on the latest techniques keeps everyone updated. Many operators often miss these trainings, reflecting a gap in practical knowledge. Adapting to new technologies can feel overwhelming, yet it’s essential for maintaining efficiency in the long run.

Understanding the Basics of Roll Stock Machines

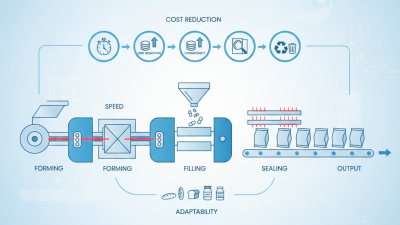

Roll stock machines are crucial in packaging industries. Understanding how they function can greatly enhance efficiency. These machines utilize large rolls of flexible packaging material, converting them into pre-formed packages. With the right setup, they can save time and reduce waste. According to industry reports, effective management of roll stock materials can decrease costs by up to 30%.

Keeping the machinery properly maintained is vital. Regular inspections can prevent unnecessary downtime. Ensuring that all components are in good condition enhances performance. It's also important to monitor the machine's speed and temperature settings. These factors significantly impact the quality of the final packaging. Operating at the right parameters can yield better results.

Tip: Invest time in training your operators. Knowledgeable staff can troubleshoot issues quickly. This minimizes production disruptions. Additionally, keeping an eye on inventory levels helps avoid material shortages. Utilizing software for tracking can provide real-time insights into usage patterns. This leads to more informed decisions and optimizes workflow. Remember, no machine is perfect. Regular reassessment of processes often leads to improvements.

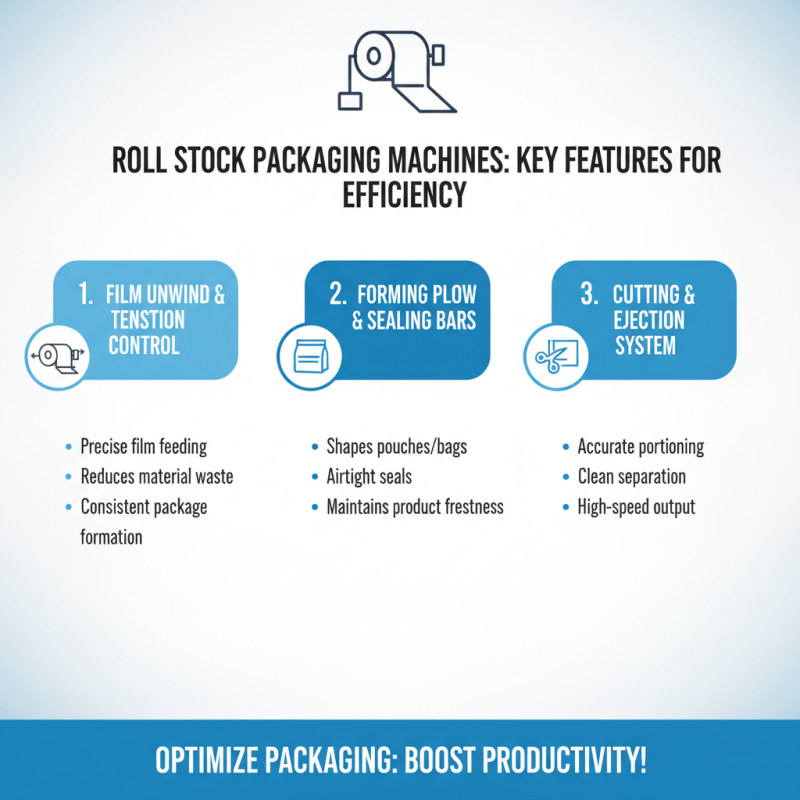

Key Features and Components of Roll Stock Machines

Roll stock machines are essential in the packaging industry. Their design includes several key features that enhance their efficiency. Understanding these components can lead to better operational strategies.

At the core of any roll stock machine is the roll stand. This is where the material roll is held. Proper loading techniques can reduce downtime. Additionally, the feeding system plays a vital role. It guides the film into the machine, impacting the accuracy of cuts. If this system is misaligned, it can cause product defects.

Moreover, the sealing unit is crucial. It creates airtight seals to protect products. Regular maintenance is vital. Worn components can lead to leaks and waste. Operators must often check the temperature settings. Inadequate temperatures can compromise seal integrity. Understanding these features allows for a more effective operation, but it’s easy to overlook them under pressure. Regular reviews of machine performance can help identify areas for improvement.

Essential Maintenance Practices for Optimal Performance

Operating a roll stock machine effectively requires consistent maintenance for optimal performance. Regularly scheduled checks are vital. According to industry reports, 80% of machine failures stem from inadequate upkeep. Simple actions can prevent costly downtime. Clean the machine daily to remove debris that can hinder performance. Lubricate moving parts weekly to reduce friction and wear.

Routine inspections should not be ignored. Check belts for wear and tear every month. A worn belt can lead to malfunction. One survey showed that 45% of operators overlook this crucial step. Replace filters regularly to ensure clean airflow. This can enhance machine efficiency significantly.

Sometimes, achieving optimal performance feels elusive. Unexpected breakdowns can occur despite best efforts. Maintaining a log of repairs and maintenance activities helps identify patterns. This data-driven approach may reveal persistent issues. Reflect on practices that may need adjustment. Be proactive rather than reactive with maintenance; the cost of neglect can be high. Regular training for staff on machine operation can also significantly reduce errors.

10 Essential Tips for Operating a Roll Stock Machine Effectively - Essential Maintenance Practices for Optimal Performance

| Tip Number | Tip Description | Frequency of Maintenance | Expected Outcome |

|---|---|---|---|

| 1 | Regularly check and clean the rollers | Weekly | Improved efficiency and reduced wear |

| 2 | Ensure proper lubrication for moving parts | Monthly | Smoother operation and reduced friction |

| 3 | Inspect and replace worn or damaged parts | Quarterly | Increased machine longevity |

| 4 | Monitor and calibrate temperature settings | Monthly | Consistent product quality |

| 5 | Train operators on best practices | Annually | Reduced errors during operation |

| 6 | Maintain clean surroundings and workspace | Daily | Enhanced safety and efficiency |

| 7 | Optimize material feed and tension settings | Before each production run | Minimized waste and defects |

| 8 | Document all maintenance activities | Ongoing | Improved tracking and accountability |

| 9 | Utilize downtime for thorough inspection | As needed | Early detection of issues |

| 10 | Conduct regular performance audits | Biannually | Continual improvement in operations |

Safety Protocols for Operating Roll Stock Machinery

Operating roll stock machinery comes with inherent risks. Safety should always be a priority. According to the National Safety Council, improper operation of machinery can lead to serious injuries. In 2020, there were over 4,500 reported injuries associated with industrial machinery in the United States. Each operator must be aware of safety protocols.

Personal protective equipment (PPE) is essential. Operators should wear safety gloves, goggles, and ear protection. These items help mitigate risks when working around heavy equipment. Regular inspections of machinery can prevent unexpected failures. Inconsistent maintenance leads to increased operational hazards. The Occupational Safety and Health Administration (OSHA) states that adherence to safety practices can reduce accidents by up to 40%.

Training is vital for all personnel. Continuing education can highlight new safety measures. Operators must understand emergency procedures. However, the application of knowledge remains inconsistent. Many fail to follow protocols under pressure. Without a strong safety culture, mistakes can happen. This leads to potential injuries and costly downtime. Understanding and reflecting on these challenges can promote a safer work environment.

Tips for Troubleshooting Common Issues in Roll Stock Operations

Operating a roll stock machine can present various challenges. Equipment jams are common. When a jam occurs, it may take time to identify the root cause. Insufficient tension can often lead to tears in the material. Checking the tension regularly is essential. If you notice inconsistent feeding, inspect the rollers. They may need adjustment or replacement.

Another frequent issue is misalignment. Misalignment can cause uneven packaging. This problem often arises from wear and tear on components. Regularly inspect the guides and frames. If they are not aligned, the machine will struggle. It’s crucial to recalibrate whenever you notice these signs.

Monitoring temperature and humidity levels in the workspace can also help. Excessive heat can warp materials. High humidity can lead to dampness, affecting product quality. Keep your workspace controlled. Documenting any operational inconsistencies is also beneficial. It helps identify patterns in machine performance. Reflection on these details can lead to improved outcomes.

Related Posts

-

What is a Filling Machine and How Does it Work in Various Industries

-

How to Operate a Roll Stock Machine Effectively?

-

How to Choose the Best Pouching Machines for Your Packaging Needs

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

-

What is a Horizontal Packaging Machine and How Does It Work?

Products

Links

© Copyright 2025 | All Rights Reserved