Experience & Vision

10 Essential Tips for Choosing the Right Wrapping Machine

Choosing the right wrapping machine can often feel overwhelming. Mark Thompson, an expert in packaging solutions, once said, "The right wrapping machine transforms efficiency." With so many options available, understanding your needs is crucial. Each machine has unique features that may suit different products or production lines.

Consideration of specific requirements leads to better decisions. For example, a machine optimized for delicate items may not handle heavy boxes well. It’s essential to analyze the types of products you’ll wrap. Evaluate the wrapping materials that work best with your chosen machine.

Reflecting on the process can reveal areas of confusion. Factors like speed, cost, and maintenance often cloud judgment. It's key to weigh each element carefully before making a final choice. Ultimately, aligning the right wrapping machine with your operations can enhance productivity.

Understanding Different Types of Wrapping Machines Available

When selecting a wrapping machine, understanding the different types available is crucial. There are several categories, each designed for specific tasks. Automatic machines work efficiently but may lack flexibility. Semi-automatic models can bridge the gap, offering both control and speed. According to a market research report by Smithers Pira, the demand for automatic wrapping machines has surged by 17% over the past three years.

Certain operations benefit from stretch wrapping. This method is ideal for securing loads, especially in the food industry. Plastic films used in stretch wrapping allow for visibility and protection. However, one must consider the type of product being wrapped. Not all machines can handle fragile items effectively. A recent survey revealed that 30% of companies face issues with machinery unsuited to their products, highlighting the importance of this choice.

Moreover, the cost can be a significant factor in decision-making. Some businesses compromise on quality to save money. Investing in a reliable machine may reduce downtime and maintenance costs in the long run. Nevertheless, many organizations might not realize this until faced with frequent breakdowns. Finding the right balance between budget and functionality is key.

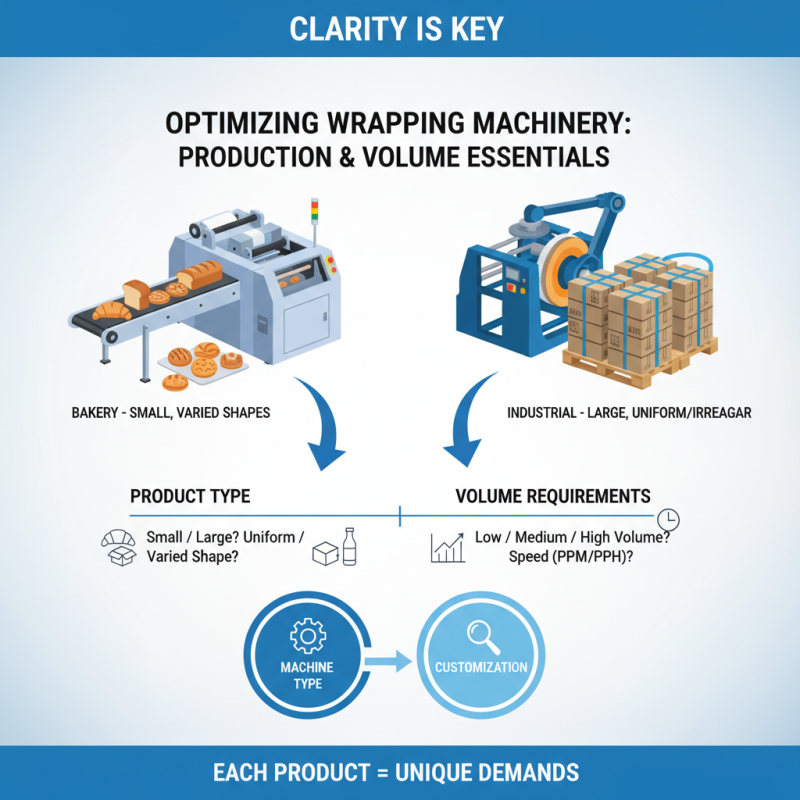

Assessing Production Needs and Volume Requirements

When assessing production needs and volume requirements for wrapping machines, clarity is key. Start by understanding the types of products you plan to wrap. Are they small or large? Do they vary in shape? This will influence your choice significantly. For example, a bakery might need different machinery compared to a manufacturer of industrial parts. Each product type often has unique wrapping demands.

Evaluate your production volume. Are you packaging hundreds or thousands of items daily? Higher volumes typically require faster machines with automated functions. However, investing in high-speed machines without addressing actual output can lead to underutilization. Additionally, consider the space available for the wrapping machine. A compact design may be necessary if floor space is limited, yet it could restrict processing capabilities.

Take note of the flexibility you require. If your production line changes frequently, select a machine that can adapt to varied products easily. It's also wise to reflect on potential maintenance needs. Regular upkeep is essential for smooth operations but can easily be overlooked. Ignoring these factors may result in costly delays or unexpected downtime. Balancing all these aspects can feel overwhelming, but it's essential for making an informed decision.

Key Features to Consider in a Wrapping Machine

When choosing a wrapper machine, several key features should guide your decision.

Consider the capacity required for your production line.

A machine that can handle your output efficiently is crucial. If your business produces 3,000 units per hour,

select a machine that meets or exceeds that requirement. A mismatch in capacity could slow down operations

and impact profitability.

Another vital feature is the type of wrapping material.

Different machines support various materials such as plastic film, paper, or biodegradable options.

Ensure the machine you choose is compatible with your preferred materials. Industry data suggests that

40% of businesses report challenges due to material compatibility issues.

This often leads to increased costs and waste.

Tip one: Look for a machine with adjustable settings.

Flexibility can save time when switching between product sizes.

Tip two: Investing in a machine with user-friendly controls

can reduce training time. Many operators struggle with complex systems,

leading to errors and frustration. Avoid machines that lack intuitive interfaces.

It’s essential for fostering efficiency on your production floor.

Evaluating Budget Constraints and Total Cost of Ownership

When choosing a wrapping machine, budget constraints play a significant role. It's important to assess both initial costs and ongoing expenses. The total cost of ownership includes maintenance, energy consumption, and downtime. These often-overlooked factors can greatly influence your overall budget. How often will the machine need repairs? Will it consume a lot of electricity? These questions matter.

Consider the operational efficiency of the machine, too. A lower purchase price may come with hidden costs. Machines that break down often lead to lost productivity. Investing in a reliable machine can save you money in the long run. Analyze warranties and support services offered by manufacturers. A good warranty can alleviate some financial burdens. However, its terms must be clear and fair.

Don’t forget to evaluate the machine's adaptability to your production needs. A machine that fits your current process may not work as your business grows. Flexibility could save money on future investments. Sometimes, spending more upfront due to quality can be wise. Reflect on past purchases that seemed cheap but didn't deliver value.

10 Essential Tips for Choosing the Right Wrapping Machine - Evaluating Budget Constraints and Total Cost of Ownership

| Criteria | Description | Estimated Cost ($) | Maintenance Cost ($/year) | Expected Lifespan (years) |

|---|---|---|---|---|

| Budget | Consider overall investment and financing options. | 15,000 | 1,200 | 10 |

| Machine Type | Select between manual and automatic machines. | 12,000 | 900 | 8 |

| Speed | Assess output speed against production needs. | 18,000 | 1,500 | 12 |

| Versatility | Ability to handle different package sizes. | 14,000 | 1,300 | 10 |

| Energy Efficiency | Consider energy consumption and savings. | 16,000 | 1,000 | 15 |

Researching and Choosing the Right Supplier for Your Needs

Choosing the right supplier for your wrapping machine is crucial. A good supplier can impact your production efficiency significantly. Begin by researching different companies. Explore their reputation within the industry. Look for reviews and testimonials from existing customers. This feedback can provide insights into reliability and service quality.

Consider the supplier's experience and expertise. Established companies often have better resources and knowledge. They can offer a range of machines tailored to your needs. Ask them about customization options. It's essential to ensure they can meet your specific requirements.

Interacting with the supplier is also important. A clear line of communication can prevent misunderstandings later. Many suppliers offer consultations. Use this opportunity to voice your needs and concerns. Occasionally, you may encounter suppliers who overpromise. Be cautious of this. Ask for measurable proof to support their claims. Make sure they align with your business goals.

Related Posts

-

Top Bagging Machinery Equipment for Efficient Packaging Solutions?

-

2025 Guide: How to Choose the Right Packaging Machinery Equipment for Your Business

-

How to Operate a Roll Stock Machine Effectively?

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Benefits of Form Fill Seal Machines in Packaging Industry

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

Products

Links

© Copyright 2025 | All Rights Reserved