Experience & Vision

How to Operate a Roll Stock Machine Effectively?

Operating a roll stock machine requires precision and attention to detail. This equipment plays a crucial role in packaging industries. It can significantly improve production efficiency when managed correctly.

Understanding the mechanics of a roll stock machine is essential. Proper setup and maintenance ensure smooth operations. Operators must be trained to handle various materials effectively. Minor mistakes can lead to costly errors.

Adjusting the machine settings can seem daunting. Regular inspections can help identify potential issues. An operator should always pay attention to product quality. However, challenges will arise, and learning from them is vital. Embracing these moments of reflection is key to mastering the roll stock machine.

Understanding the Basics of Roll Stock Machines

Roll stock machines are essential in various industries. They facilitate the packaging process by unwinding film or paper. Understanding the basics helps operators ensure efficiency and reduce waste. Operators must be familiar with the machine's components like the unwind and rewind stations. Setting the tension correctly is crucial. Improper tension can lead to creases or tears in the material.

Training is necessary to operate these machines efficiently. Operators should know how to adjust settings based on the material type. Regular maintenance is necessary. However, even with proper care, issues may arise. Misalignment or film jams can occur. When these problems happen, troubleshooting is key. Identifying the root cause quickly can save time and materials.

Communication with team members is vital. Sharing insights on what works or doesn’t can enhance overall operations. Each operator may have different experiences. Learning from each other can lead to better practices. Maintenance logs can help track recurring issues. Reflection on these entries may lead to improvements in machine operation.

Roll Stock Machine Efficiency Metrics

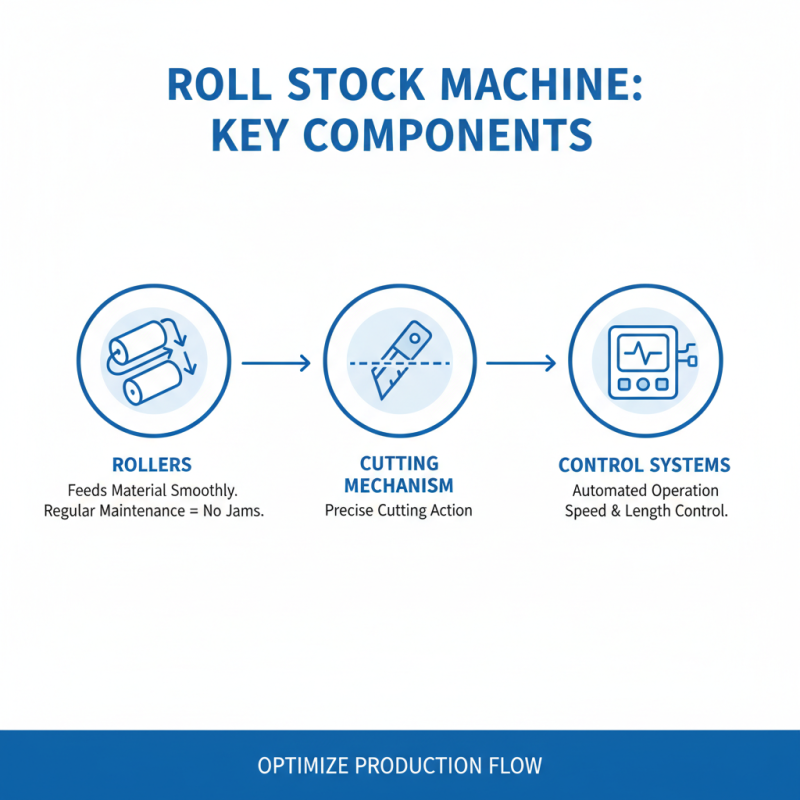

Key Components and Their Functions in Roll Stock Operation

Understanding the key components of a roll stock machine is crucial for effective operation. A roll stock machine typically features rollers, a cutting mechanism, and control systems. The rollers feed material into the machine. They must operate smoothly; otherwise, the production may slow down. Regular maintenance on the rollers can help avoid jammed operations.

The cutting mechanism is essential. It needs to be sharp and well-calibrated to ensure quality cuts. A dull blade can lead to uneven products, resulting in waste. Operators should check the blade frequently. Control systems allow users to set parameters for speed and precision. Ineffective settings can disrupt the whole production process. It’s important to recalibrate these settings based on material type.

Regularly inspecting these components enhances overall performance. However, many overlook minor issues until they escalate. Operators may feel the urge to push through delays instead of addressing them. This mindset can lead to bigger problems down the line. Small changes, like tightening a loose screw, can make a significant difference. Overall, awareness of these components truly impacts the effectiveness of roll stock machine operation.

Step-by-Step Guide to Setting Up a Roll Stock Machine

Setting up a roll stock machine requires careful attention. Begin by selecting a suitable location with ample space. Ensure the area is clean and free of obstructions. Check the machine's manual for specific requirements on positioning and installation. You want the machine to be easily accessible for operation and maintenance.

Once positioned, load the roll stock correctly. Align the roll with the feeding mechanism. This step is essential for consistent performance. Some operators struggle with this part, leading to frequent jams. Take your time to ensure everything is in place. Adjust the settings based on the material and thickness of the roll. Incorrect settings can result in poor output quality.

After setup, run a few test cycles. Watch for any deviations or issues. If problems arise, it’s crucial to troubleshoot immediately. Analyze what went wrong. Sometimes, it's the tension that's off. Other times it might be the alignment. Monitoring the machine regularly can prevent larger issues down the line. Remember, every setup requires patience and practice. Don't be discouraged by initial challenges.

How to Operate a Roll Stock Machine Effectively? - Step-by-Step Guide to Setting Up a Roll Stock Machine

| Step | Description | Tools Needed | Estimated Time |

|---|---|---|---|

| 1 | Check Power Supply | Multimeter | 10 minutes |

| 2 | Load Raw Material | Roll Stock | 15 minutes |

| 3 | Set Machine Parameters | Control Panel | 20 minutes |

| 4 | Perform Test Run | None | 30 minutes |

| 5 | Start Production | None | Ongoing |

| 6 | Monitor Output Quality | Quality Control Tools | Ongoing |

Best Practices for Maintaining Roll Stock Machines

Maintaining roll stock machines is crucial for optimal operation. Regular maintenance checks can lead to improved efficiency. A recent industry report indicated that well-maintained machinery can produce up to 20% more output. This is a significant increase in productivity, but many operators still overlook regular inspections.

Cleaning the machine is a vital step often neglected. Dust and debris can lead to mechanical failures. A study found that 30% of machine malfunctions stem from poor cleaning practices. Operators should schedule daily cleanings. Inspecting rollers and guides is essential. Wearing parts can cause misalignment and waste materials.

Training operators is another key aspect. Many companies skip this step, leading to mistakes. Data shows that 25% of workplace accidents involve untrained staff. Creating a training program can mitigate risks. It should cover machine handling, maintenance procedures, and safety protocols. Regularly reviewing these practices can reveal areas for improvement. Ignoring these factors may lead to increased downtime and repair costs.

Common Troubleshooting Tips for Roll Stock Machine Issues

Operating a roll stock machine can pose challenges, particularly when issues arise. A recent industry report indicates that approximately 30% of roll stock machine downtime is attributed to troubleshooting. This figure stresses the need for effective diagnostic practices. Common problems include film misalignment, sealing failures, and inconsistent tension. Identifying these issues quickly can save production time.

Film misalignment often occurs due to incorrect setup or operator error. Regular checks of the feed rolls can help maintain proper alignment. According to some experts, maintaining a tension level within 5-10% of the specified range improves performance. Inconsistent tension may lead to uneven cuts, causing waste. Adjusting the tension settings before production begins is crucial.

Sealing difficulties are another frequent headache. Operators must ensure that the sealing temperature meets manufacturer specifications. This simple tip can avoid costly rejects. Additionally, worn-out sealing jaws can lead to poor quality seals, requiring replacement. It’s vital to regularly assess and replace these components. Monitoring these aspects could reduce machine downtime by up to 20%. Effective troubleshooting not only addresses current issues but also enhances overall operational efficiency.

Related Posts

-

Top 10 Benefits of Form Fill Seal Machines in Packaging Industry

-

What is a Filling Machine and How Does it Work in Various Industries

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

Products

Links

© Copyright 2025 | All Rights Reserved