Experience & Vision

How to Choose the Right Form Fill Packaging Machine for Your Business Needs

Choosing the right form fill packaging machine for your business is a critical decision that can significantly impact your production efficiency and product presentation. In the fast-paced world of manufacturing and retail, the ability to efficiently package products not only enhances shelf appeal but also ensures that goods are preserved and protected until they reach the end consumer. With various options available in the market, understanding the unique demands of your business is key to selecting a machine that aligns with your operational needs.

Form fill packaging machines come in a variety of specifications and functionalities, making it essential to evaluate factors such as the volume of production, the type of products being packaged, and the desired packaging format. By carefully analyzing these elements, businesses can determine which features are imperative for their specific applications, leading to increased productivity and lower operational costs. When equipped with the right form fill packaging machine, companies can streamline their packaging process, ultimately enhancing customer satisfaction and fostering growth in a competitive marketplace.

Understanding the Basics of Form Fill Packaging Machines

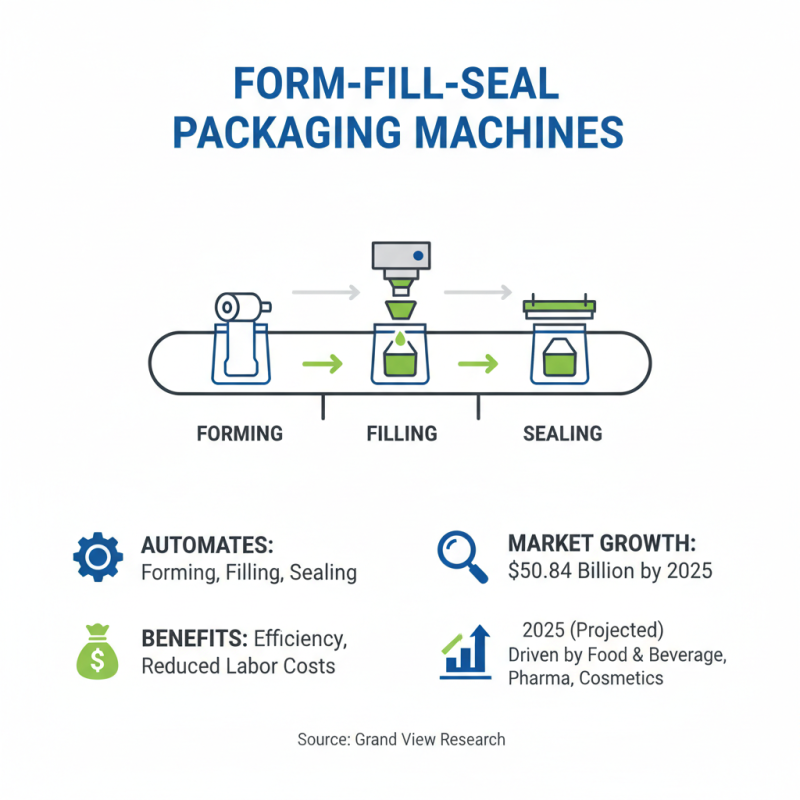

Form fill packaging machines play a crucial role in modern manufacturing processes, enabling businesses to efficiently package products while reducing labor costs. At their core, these machines automate the process of forming, filling, and sealing packages, which streamlines production lines. According to a report by Grand View Research, the global form fill seal packaging market is projected to reach USD 50.84 billion by 2025, driven by increasing demand for efficient packaging solutions in the food and beverage, pharmaceutical, and cosmetic industries. This data underscores the importance of understanding the mechanics behind these machines to make informed purchasing decisions.

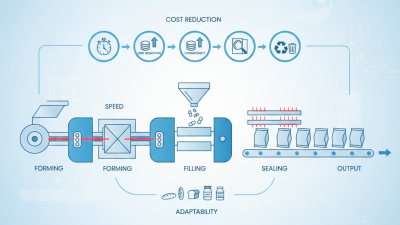

When evaluating form fill packaging machines, it is important to consider several key factors that influence performance and suitability for specific applications. First, the type of materials being used impacts the choice of machine; some packaging machines are designed for flexible materials, while others are better suited for rigid containers. Additionally, the machine's speed and production capacity should align with the business's output requirements. Industry experts recommend considering the technical specifications, such as the filling accuracy and sealing capability, to ensure they meet your operational needs. According to a report by MarketsandMarkets, advancements in technology are enabling higher precision in these machines, which can lead to reduced waste and enhanced product integrity, providing further incentive to invest in high-quality packaging solutions.

Assessing Your Production Volume and Speed Requirements

When selecting the appropriate form fill packaging machine for your business, it is essential to assess your production volume and speed requirements. According to a report by MarketsandMarkets, the global packaging machinery market is projected to grow from $45.3 billion in 2021 to $65.4 billion by 2026, with a compound annual growth rate (CAGR) of 7.8%. This growth underscores the importance of investing in machinery that aligns with your production needs, especially as demand for high-volume packaging continues to rise.

For manufacturers processing small to medium batches, a machine with a throughput of 30-50 units per minute may suffice. However, businesses experiencing rapid growth or operating within high-demand industries, such as food and beverage or pharmaceuticals, may require equipment capable of speeds exceeding 100 units per minute. A detailed analysis of your current and projected production volumes will aid in determining the best machine specification. Incorporating this data will enhance operational efficiency and reduce bottlenecks, ensuring you can meet market demands without compromising quality.

For manufacturers processing small to medium batches, a machine with a throughput of 30-50 units per minute may suffice. However, businesses experiencing rapid growth or operating within high-demand industries, such as food and beverage or pharmaceuticals, may require equipment capable of speeds exceeding 100 units per minute. A detailed analysis of your current and projected production volumes will aid in determining the best machine specification. Incorporating this data will enhance operational efficiency and reduce bottlenecks, ensuring you can meet market demands without compromising quality.

Evaluating Different Types of Form Fill Machines Available

When considering the right form fill packaging machine for your business, it's essential to evaluate the different types available in the market. The primary categories include vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, and pouch packaging machines. According to a report by MarketsandMarkets, the global form fill seal packaging market is projected to grow at a CAGR of 5.8% from 2020 to 2025, emphasizing the increasing demand for efficient packaging solutions across various industries.

Vertical form fill seal machines are particularly popular for packaging products like snacks, grains, and liquids. They allow for high-speed packaging and are ideal for products that require gravity to move through the machine. Conversely, horizontal form fill seal machines are better suited for items that need a more stable platform during packaging, such as fragile items or larger products. Data from a recent industry analysis indicates that VFFS machines account for nearly 61% of the total market share due to their versatility and efficiency in high-volume production.

Additionally, pouch packaging machines are gaining traction in sectors like food and beverage, personal care, and pharmaceuticals, as they provide an innovative solution for single-serve options and reduce material waste. The flexibility of these machines allows for various pouch designs and sizes, making them an attractive option for businesses aiming to enhance their product presentation. As the demand for sustainable and customizable packaging continues to rise, selecting the right form fill packaging machine becomes crucial for businesses to meet both operational goals and consumer expectations.

Key Features to Consider When Selecting a Machine

When selecting a form fill packaging machine, it's essential to consider several key features that can significantly impact your productivity and product quality. First and foremost, the machine's versatility is crucial. Ensure it can handle various packaging materials and sizes to accommodate your product range. This flexibility allows you to adapt to changing market demands without needing extensive equipment changes.

Another important feature is the ease of operation and maintenance. Look for machines equipped with user-friendly controls and automation features that simplify the packaging process. A machine that requires minimal training to operate can save time and reduce errors on the production line. Additionally, consider machines with easy access for maintenance to minimize downtime and keep your operations running smoothly.

Tip: Always prioritize machines with robust safety features to protect your employees during operation.

Lastly, pay attention to the machine's speed and efficiency. High-speed machines can significantly boost your output, but it's crucial to strike a balance between speed and packaging integrity. Assess your production goals and choose a machine that meets your throughput requirements while ensuring quality packaging.

Tip: Run a trial of the machine's capabilities before making a purchase to ensure it aligns with your production needs.

Budgeting for Costs: Initial Investment vs. Long-term Value

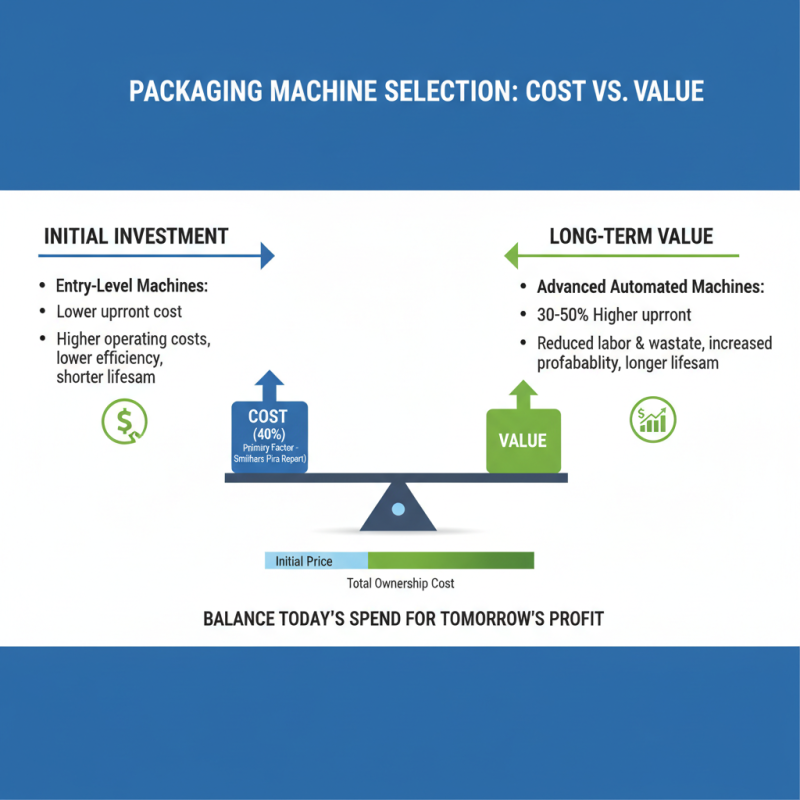

When selecting the right form fill packaging machine for your business, it's crucial to balance initial investment with long-term value. According to a report by Smithers Pira, nearly 40% of manufacturers consider cost as the primary factor in machine selection. The initial price you pay can vary significantly based on the technology, automation level, and machine capabilities. Entry-level machines may seem more attractive financially, but they often come with higher operating costs, lower efficiency rates, and shorter lifespans. For instance, investing in a more advanced automated packaging machine may have an upfront cost that is 30-50% higher, but this can translate to savings on labor and wastage in the long run, ultimately improving your overall profitability.

Furthermore, an effective machine should enhance your production capabilities and adapt to changing market demands. A report from PMMI estimates that packaging innovations can reduce transportation and labor costs by up to 20%. This statistic underscores the potential for a higher-performing machine to yield significant returns over its operational life. Evaluating total cost of ownership, which includes maintenance, energy use, and downtime, is essential to understand the true value of your investment. Businesses focusing solely on initial costs risk underestimating the financial benefits of quality machinery, which can enhance productivity and ensure more agile responses to market opportunities.

Related Posts

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

-

Top 10 Tips for Choosing the Best Overwrapping Machines for Your Business

-

Top 5 Benefits of Using Fill and Seal Machines for Efficient Packaging

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

Products

Links

© Copyright 2025 | All Rights Reserved