Experience & Vision

How to Choose the Best Pouching Machines for Your Packaging Needs

In the ever-evolving landscape of packaging technology, selecting the right pouching machines can significantly impact efficiency, cost-effectiveness, and product integrity. According to industry expert Dr. Emily Carter, a leading authority on packaging solutions, “Investing in the right pouching machines can transform your production line, enhancing both speed and quality.” As businesses strive to meet the increasing demand for flexible packaging, understanding the various options available is crucial.

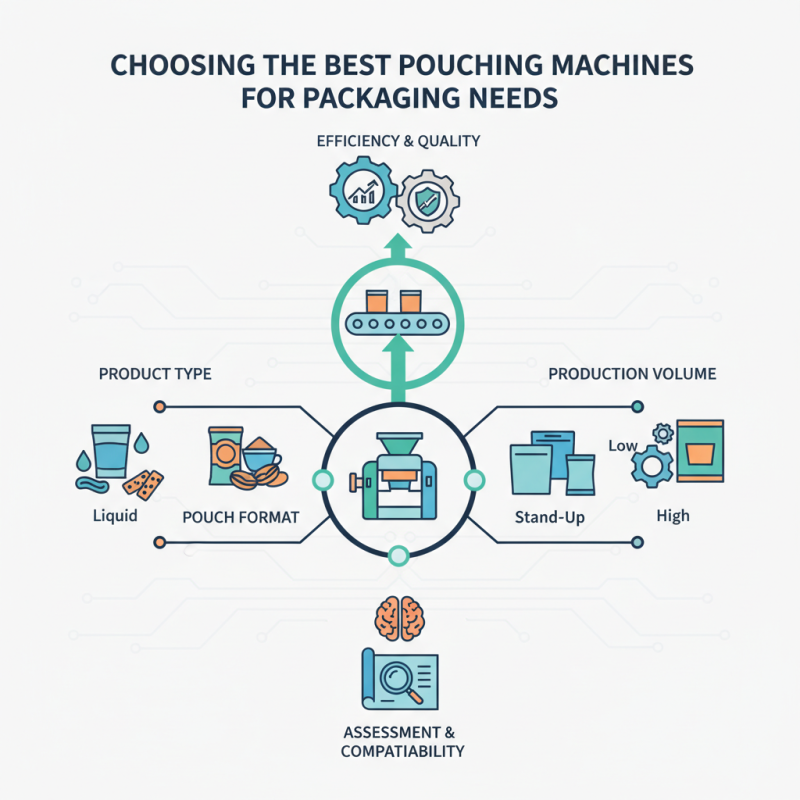

Pouching machines come in different configurations and capabilities, each tailored to specific packaging needs. Factors such as the type of product, desired pouch format, and production volume are essential in determining the most suitable machine for your operations. Furthermore, advancements in technology have led to a surge in innovative designs that offer enhanced automation and precision, making it vital for decision-makers to stay informed about the latest trends and features within the industry.

Choosing the best pouching machines is not merely a matter of price but requires a comprehensive assessment of functionality and compatibility with existing processes. With the right insights and guidance, businesses can optimize their packaging strategies and achieve sustainable growth in a competitive market.

Understanding the Different Types of Pouching Machines in the Market

When selecting a pouching machine for your packaging needs, it's essential to understand the various types available in the market. The most common types include vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and pre-made pouch machines. VFFS machines operate by creating pouches from a flat roll of film, filling them with products, and sealing them in a continuous flow. This makes them ideal for dry goods like snacks or powders, where speed and efficiency are crucial.

On the other hand, HFFS machines are designed for products that require a more complex filling process, such as liquids or granulated items. These machines form pouches horizontally and can accommodate a range of shapes and sizes, making them versatile for various products. Lastly, pre-made pouch machines utilize pre-formed pouches, which can streamline the filling process for certain businesses. They allow for greater customization in pouch design and are perfect for items needing specific bag shapes or enhancing shelf appeal. Understanding these differences will help businesses select the right pouching machine that aligns with their product specifications and packaging goals.

Types of Pouching Machines and Their Applications

Evaluating Production Speed and Efficiency of Pouching Machines

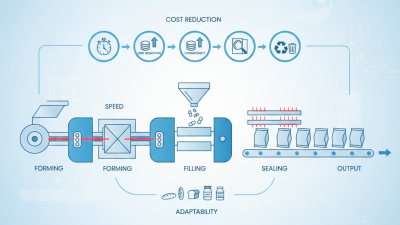

When selecting the appropriate pouching machines for your packaging needs, evaluating production speed and efficiency is paramount. Recent industry studies indicate that high-speed pouching machines can significantly enhance production lines, with some capable of achieving speeds upwards of 300 pouches per minute. This level of output not only accelerates the packaging process but also helps in meeting growing consumer demand, which has increased by approximately 10% annually in the flexible packaging sector. Thus, choosing a machine with optimized speed capabilities can lead to substantial gains in overall productivity.

Efficiency is another critical factor to consider. According to a report by the Flexible Packaging Association, the overall equipment effectiveness (OEE) of pouching machines can vary greatly, typically ranging from 60% to 85%. A machine that operates at a higher OEE ensures less downtime and minimal waste, directly impacting profitability. Factors influencing efficiency include changeover times and the ease of maintenance; machines designed for quick adjustments can maintain operational flow, thereby improving throughput.

By closely examining these aspects of production speed and efficiency, businesses can better align their pouching machine choices with their operational goals, ultimately driving success in their packaging processes.

Assessing the Versatility and Compatibility of Pouching Machines

When selecting a pouching machine for your packaging needs, versatility and compatibility become pivotal factors that can significantly influence your operational efficiency. A versatile pouching machine should accommodate different pouch sizes, styles, and materials, thereby enabling manufacturers to diversify their product offerings without the need for multiple machines. This flexibility is crucial for businesses looking to adapt to changing market demands or to optimize their production processes by switching between various products seamlessly.

Compatibility with existing production lines and packaging materials is equally important. A machine that can easily integrate with your current setup will minimize downtime during the transition period and ensure a smoother workflow. Additionally, assessing the compatibility with various pouch materials, such as laminates or biodegradable options, can provide significant advantages in meeting consumer preferences and sustainability goals. By prioritizing these factors, businesses can make more informed decisions, ensuring their pouching machines align well with both their current and future packaging strategies.

Identifying Key Features and Specifications for Effective Packaging

When selecting the best pouching machines for your packaging needs, it is crucial to identify key features and specifications that will ensure efficiency and effectiveness. One vital factor to consider is the machine's throughput capacity. According to industry reports, packaging lines requiring a production rate of up to 120 pouches per minute typically rely on high-efficiency machines designed for rapid output without compromising on quality. Examining the machine’s filling accuracy and versatility to handle various pouch sizes and materials can greatly affect the overall packaging process.

Moreover, usability and maintenance play significant roles in the long-term value of pouching machines. A user-friendly interface reduces training time and minimizes operational errors. For instance, machines equipped with touch-screen controls and automated cleaning systems offer an advantage in reducing downtime and ensuring consistent quality. Additionally, looking for models with built-in sensors to monitor fill levels and seal integrity can provide real-time feedback, allowing for timely adjustments to prevent waste. According to a recent study published by the Packaging Machinery Manufacturers Institute (PMMI), nearly 60% of companies reported increased efficiency with machines that include such smart technologies, underscoring the importance of advanced features in optimizing packaging operations.

Analyzing Cost-Effectiveness and ROI of Pouching Machine Investments

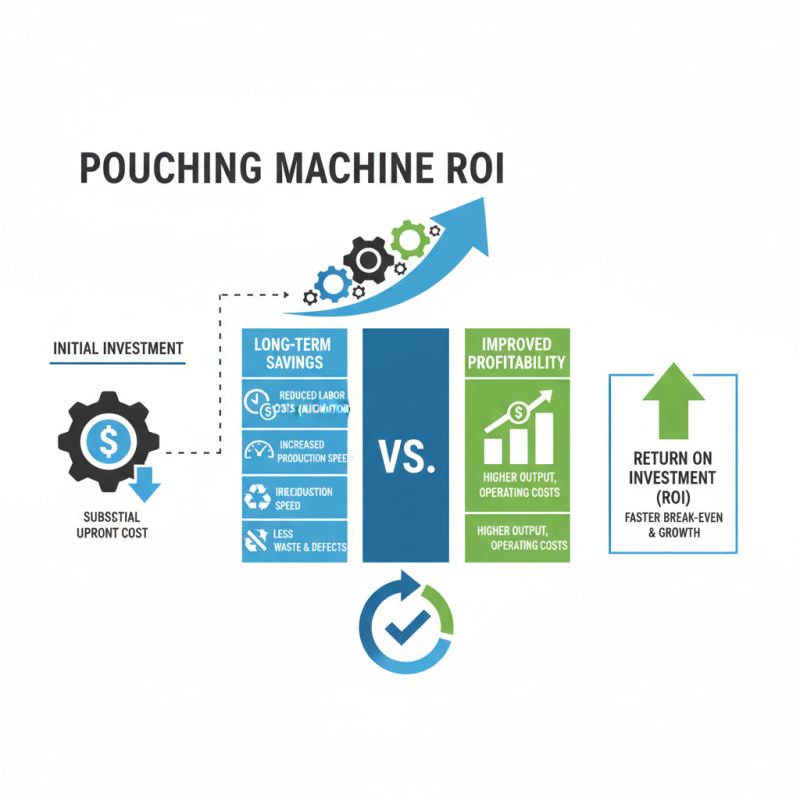

When investing in pouching machines, understanding the cost-effectiveness and return on investment (ROI) is crucial. The initial expenditure of purchasing a machine can be substantial; however, this upfront cost should be balanced against long-term savings and efficiencies. Pouching machines can significantly reduce labor costs by automating processes that would otherwise require multiple operators. Additionally, they are capable of increasing production speed and consistency, leading to fewer product defects and less waste, all of which contribute to improved profitability over time.

Moreover, evaluating the ROI of pouching machines involves considering factors like operational lifespan, maintenance costs, and efficiency gains. A machine that operates efficiently with minimal downtime can enhance a company’s output and minimize operational disruptions. It's also essential to consider the flexibility of the pouching machines being offered; those adaptable to various pouch sizes and materials can better serve evolving packaging needs, thereby extending their value. Ultimately, assessing both the direct costs and the broader impacts on production processes will guide businesses in making informed decisions that align with their packaging needs and financial objectives.

Related Posts

-

What is a Filling Machine and How Does it Work in Various Industries

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

How to Choose the Right Form Fill Packaging Machine for Your Business Needs

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

-

Top 5 Benefits of Using Fill and Seal Machines for Efficient Packaging

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

Products

Links

© Copyright 2025 | All Rights Reserved