Experience & Vision

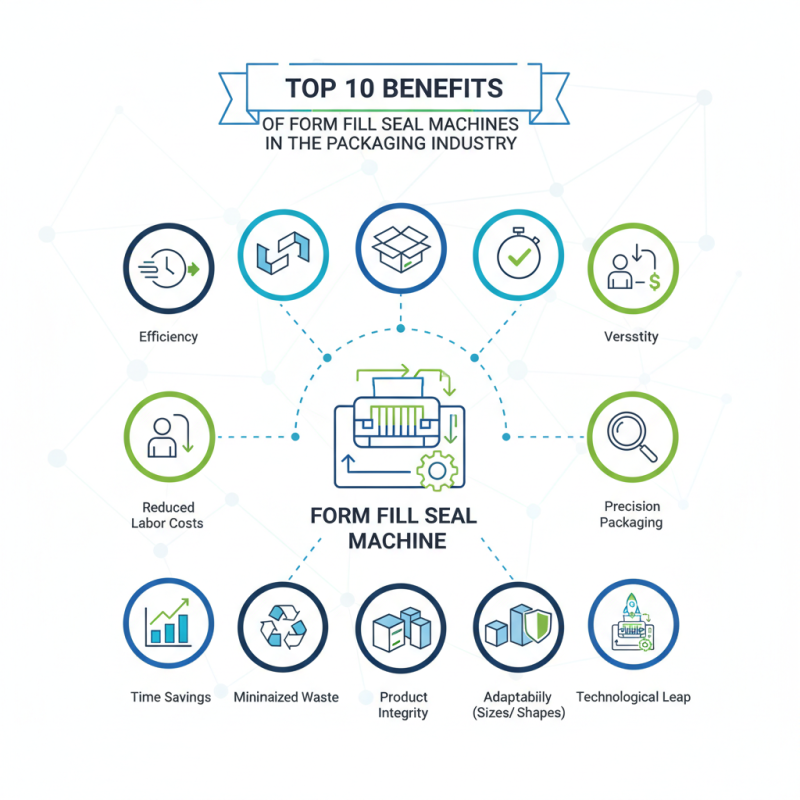

Top 10 Benefits of Form Fill Seal Machines in Packaging Industry

In the rapidly evolving packaging industry, the form fill seal machine stands out for its efficiency and versatility. According to Dr. Emily Parker, a leading expert in packaging technology, “The advancements in form fill seal machines have transformed production lines dramatically.” These machines combine the processes of forming, filling, and sealing in one continuous motion, reducing both time and labor costs significantly.

The benefits of form fill seal machines extend beyond mere efficiency. They offer precision in packaging, which helps in minimizing waste and ensuring product integrity. Many manufacturers have noted their ability to adapt to various sizes and shapes, making them suitable for diverse products. However, some may overlook the initial investment required for these machines. This aspect can create hesitation among small businesses, which might fear scalability issues.

Despite their challenges, the form fill seal machine represents a technological leap. This juxtaposition of speed and complexity can sometimes lead to operational pitfalls. Companies must invest time in training staff to utilize these machines effectively. The balance between innovation and practical application creates a dynamic environment where potential thrives, yet imperfections remain. Understanding this landscape is crucial for businesses aiming to harness the full potential of form fill seal machines.

Understanding Form Fill Seal Machines in Packaging

Form fill seal machines play a crucial role in the packaging industry. These machines automate the process of forming, filling, and sealing pouches or bags for various products. They are commonly used for food, pharmaceuticals, and consumer goods. By creating a package in one continuous line, they help save time and labor costs.

One of the key advantages is efficiency. The rapid production speeds can reach up to hundreds of packages per minute. This speed can lead to higher output, but it may also come with a quality control challenge. Machines may experience occasional errors, leading to product waste. It's essential for manufacturers to constantly monitor output quality for optimal results.

Customization is another important factor. Form fill seal machines allow for different shapes, sizes, and designs. This flexibility helps brands stand out on shelves. However, the setup process may require careful adjustments, which can be time-consuming. Finding the right balance between customization and efficiency can be tricky. Regular training for operators is vital to minimize such challenges.

Enhanced Efficiency of Form Fill Seal Machines

Form fill seal machines are revolutionizing the packaging industry. Their enhanced efficiency plays a crucial role in streamlining operations. These machines automatically create, fill, and seal packets. This reduces labor costs and minimizes human error.

Most machines operate quickly. They can produce hundreds of packages per minute. This speed is essential for meeting high demand. However, not all setups are perfect. Some machines may require frequent adjustments. Operators must be trained to manage these intricacies effectively.

Additionally, form fill seal machines can adapt to various products. They handle liquids, solids, and powders alike. This flexibility is valuable in a diverse market. Yet, the initial investment can be daunting. Businesses should consider their long-term needs before purchasing.

Top 10 Benefits of Form Fill Seal Machines in Packaging Industry

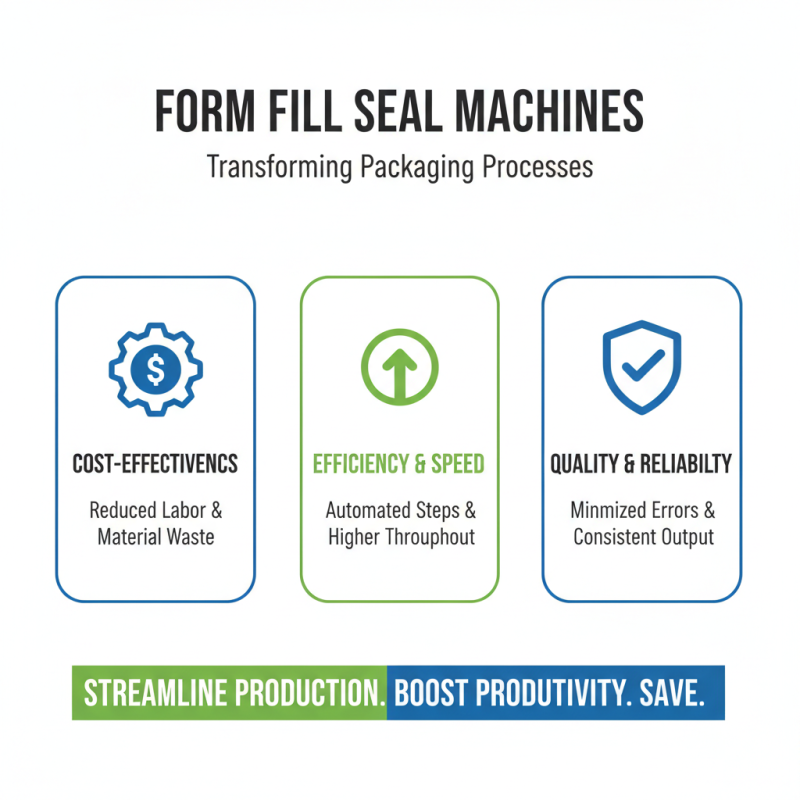

Cost-Effectiveness in the Packaging Process

The packaging industry thrives on efficiency and cost-effectiveness. Form fill seal machines are transforming packaging processes, providing significant savings. These machines automate several steps, reducing labor costs and human error. By streamlining production, they enhance productivity without compromising quality.

One tip to maximize cost-effectiveness is to customize machine settings for various products. Each item may require different sealing techniques. Adjusting the machine can prevent material waste and ensure consistent quality. Not every setting will work for every product, so testing is crucial.

Investing in form fill seal machines may seem costly upfront. However, the return on investment becomes evident with increased output. Companies should track their savings over time. While these machines boost efficiency, one must also consider maintenance costs. A well-maintained machine performs better, but unexpected breakdowns can lead to losses. Plan maintenance schedules to mitigate this.

Improved Product Quality with Form Fill Seal Technology

Form fill seal technology significantly enhances product quality in the packaging industry. This method ensures that products are sealed immediately after being filled. Such swift processing reduces contamination risks. The airtight seals created help maintain freshness. This is vital for perishable items like food and pharmaceuticals. Many users notice extended shelf life and better taste for food products packaged this way.

The precision of form fill seal machines plays a crucial role. They offer consistent fills, which minimizes waste. However, achieving this perfection can be a challenge. Variations in material thickness or temperature can lead to defects. It’s important to regularly check equipment calibration. Additionally, training operators can help prevent human errors during operation. Keeping a close eye on these factors is necessary for maintaining high product standards.

Top 10 Benefits of Form Fill Seal Machines in Packaging Industry - Improved Product Quality with Form Fill Seal Technology

| Benefit | Description | Industry Impact |

|---|---|---|

| Enhanced Seal Integrity | Provides reliable sealing which prevents leakage and maintains product freshness. | Reduces product spoilage and returns due to packaging failures. |

| Increased Efficiency | Speeds up the packaging process through automation. | Minimizes labor costs and maximizes output capacity. |

| Cost Reduction | Lowers material costs by reducing waste and optimizing packaging material use. | Boosts profit margins for manufacturers. |

| Versatility | Accommodates various products and packaging sizes. | Meets diverse market demands and product variants. |

| Improved Product Hygiene | Minimizes human contact during the packaging process. | Enhances food safety and compliance with health standards. |

| Consistent Quality Control | Ensures uniform packaging and reduces product variability. | Improves customer satisfaction through reliability. |

| Sustainability | Enables the use of eco-friendly materials and efficient processes. | Supports corporate social responsibility initiatives. |

| Custom Branding Opportunities | Allows for unique designs and branding on packages. | Enhances brand recognition and market positioning. |

| Faster Market Response | Shortens lead times for product launches and updates. | Increases competitiveness in fast-paced markets. |

| Advanced Technology Integration | Facilitates the incorporation of smart technologies in packaging. | Improves traceability and inventory management capabilities. |

Versatility and Adaptability in Various Packaging Applications

Form fill seal machines offer remarkable versatility in the packaging industry. These machines can handle various materials, including plastic and paper. This flexibility allows manufacturers to create packages for different products while maintaining efficiency. From food items to medical supplies, the range is impressive. Additionally, they adapt to various shapes and sizes, meeting diverse market demands.

These machines also support fast production rates. However, the speed can sometimes compromise quality control. Without proper oversight, minor defects may go unnoticed. Regular maintenance and checks can mitigate this issue. Integrating automation can enhance performance, yet it requires an upfront investment that not all businesses can afford. Balancing cost and efficiency is crucial for companies looking to thrive.

Durability is another feature of these machines. They withstand intense use in busy environments. Still, some operators may find them challenging to set up initially. Training staff adequately ensures smooth operations. Continuous learning is important in this ever-changing industry. Adapting to new technologies can be a hurdle, but it is necessary for growth.

Related Posts

-

What is a Filling Machine and How Does it Work in Various Industries

-

What is Packaging Equipment and How to Choose the Right One for Your Needs

-

How to Choose the Best Pouching Machines for Your Packaging Needs

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

-

What is a Horizontal Packaging Machine and How Does It Work?

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

Products

Links

© Copyright 2025 | All Rights Reserved