Experience & Vision

Top 5 Benefits of Using Fill and Seal Machines for Efficient Packaging

In today's fast-paced manufacturing environment, efficiency is paramount, particularly in the realm of packaging. One of the revolutionizing tools that has emerged is the fill and seal machine. Designed to streamline the packaging process, this innovative equipment not only enhances productivity but also ensures consistent quality across various industries. As businesses strive to keep pace with the increasing demand for packaged products, understanding the benefits of utilizing a fill and seal machine becomes essential for maintaining a competitive edge in the market.

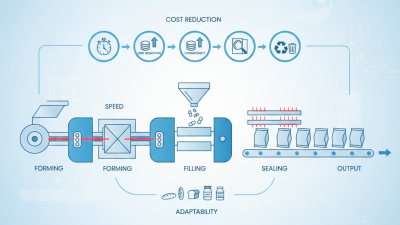

The fill and seal machine integrates multiple functions into a single system, allowing for the seamless filling, sealing, and packaging of products. This automation reduces the risk of human error, speeds up production timelines, and minimizes material waste, all contributing to cost-effectiveness. Moreover, by ensuring precise filling and airtight sealing, these machines help preserve product integrity and extend shelf life, attributes that are critical in industries such as food and pharmaceuticals.

As we delve into the top five benefits of using fill and seal machines, it will be clear how this technology not only boosts efficiency but also enhances overall operational effectiveness. Organizations that adopt this advanced packaging solution position themselves for long-term success in an ever-evolving marketplace.

Advantages of Fill and Seal Machines in Packaging Operations

Fill and seal machines have revolutionized packaging operations by delivering a level of efficiency that manual methods simply cannot match. One of the standout advantages of these machines is their ability to significantly reduce labor costs. With automation, fewer workers are needed to manage the packaging process, allowing businesses to allocate resources more effectively. This not only enhances productivity but also minimizes the risk of human error, ensuring that products are packaged consistently and accurately.

Another key benefit of fill and seal machines is their versatility. These machines are designed to handle a variety of products and packaging formats, from liquids to powders and from pouches to bottles. This flexibility enables companies to adapt their packaging strategies quickly to meet changing market demands or customer preferences. Additionally, the speed at which fill and seal machines operate can lead to faster turnaround times, helping businesses keep pace with market trends and customer orders while maintaining high-quality standards. This blend of efficiency and adaptability positions fill and seal machines as an essential asset in modern packaging operations.

Top 5 Benefits of Using Fill and Seal Machines for Efficient Packaging

Enhanced Efficiency in Production and Labor Savings

Fill and seal machines have revolutionized the packaging industry by significantly enhancing efficiency in production processes. These automated systems are designed to optimize the speed at which products are packaged, allowing businesses to process higher volumes in shorter time frames. By streamlining operations, companies can meet market demands more effectively, reducing the risk of delays and ensuring that products are available when consumers need them.

In addition to boosting production efficiency, fill and seal machines contribute to substantial labor savings. With automation taking over repetitive and time-consuming tasks, businesses can reduce their reliance on manual labor, leading to lower operational costs. This shift allows workers to focus on more complex roles that require human oversight, such as quality control and maintenance, thereby increasing overall productivity. Furthermore, the reduced need for manual intervention decreases the likelihood of human error, resulting in higher consistency and quality in packaged goods.

Improved Product Freshness and Shelf Life

Using fill and seal machines in packaging processes significantly enhances product freshness and shelf life, especially for perishable goods. These machines efficiently create airtight seals, which are crucial in preventing the entry of oxygen and moisture. By minimizing exposure to these elements, manufacturers can protect their products from spoilage and degradation. The controlled environment in which products are sealed ensures that flavors, aromas, and nutritional values are preserved, providing consumers with a superior product that is both flavorful and safe to consume.

Moreover, the automation provided by fill and seal machines streamlines the packaging process, reducing the time products spend in transit and storage before reaching the consumer. With faster packaging times, products can be distributed quickly to retailers, enhancing their freshness upon arrival. This swift turn-around not only satisfies consumer demands for fresh products but also reduces waste and losses associated with expired or spoiled items. Businesses benefit from improved customer satisfaction while simultaneously extending the shelf life of their offerings, ultimately leading to increased profitability and market competitiveness.

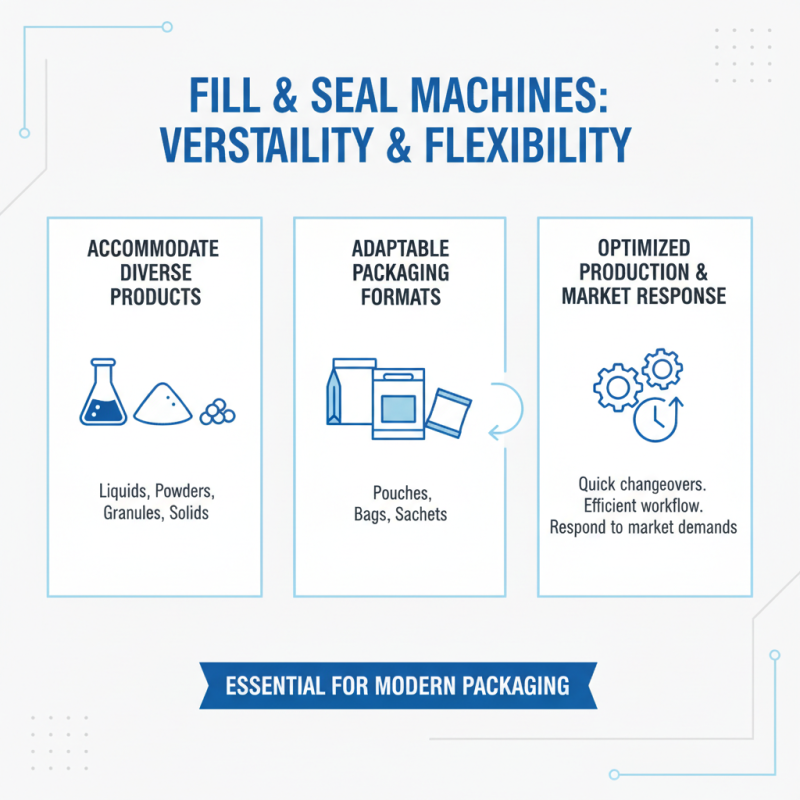

Versatility and Flexibility for Various Packaging Needs

Fill and seal machines offer remarkable versatility and flexibility, making them an essential tool in modern packaging operations. These machines can accommodate a wide range of products, from liquids and powders to granules and solid items. Their adaptability allows manufacturers to switch between different packaging formats, such as pouches, bags, and sachets, quickly and efficiently. This flexibility not only optimizes production workflow but also helps businesses respond swiftly to changing market demands, ensuring that packaging solutions align with customer preferences.

When considering the integration of fill and seal machines, it’s helpful to keep a few tips in mind. First, assess the types of products you plan to package and ensure that the machine specifications align with your product characteristics. For instance, dense powders might require different handling compared to liquids or fragile items. Second, consider investing in machines with adjustable settings that allow for quick changes in formatting and size adjustments. This capability can significantly reduce downtime and enhance overall productivity.

Furthermore, understanding the various sealing techniques can improve packaging quality and integrity. Different products may require heat sealing, vacuum sealing, or even ultrasonic sealing, depending on their specific needs. Evaluating these options based on your product will ensure a longer shelf life and better protection against contamination. By leveraging the versatility of fill and seal machines, businesses can enhance their packaging processes while catering to diverse consumer requirements.

Cost-Effectiveness and Reduction of Material Waste

The implementation of fill and seal machines in packaging processes presents a significant advantage in terms of cost-effectiveness and reduction of material waste. These machines streamline operations by automating the filling and sealing stages, which minimizes labor costs and reduces the time taken to complete each packaging cycle. By optimizing the workflow, companies can allocate resources more efficiently, leading to lower operational costs overall.

In addition to cost savings, fill and seal machines significantly contribute to reducing material waste. Traditional packaging methods often result in excess material being used, whether through miscalculations, oversizing of packaging, or product spillage.

Fill and seal technology allows for precise measurement and application, ensuring that only the necessary materials are utilized for each package. This efficiency not only lowers the environmental impact associated with packaging waste but also enhances sustainability efforts, as businesses strive to minimize their footprint and promote eco-friendly practices. As a result, the use of fill and seal machines aligns with both economic benefits and environmental responsibility.

Conclusion

Fill and seal machines offer numerous advantages that greatly enhance packaging operations. One of the primary benefits is their ability to significantly increase efficiency in production, which translates to substantial labor savings. These machines streamline the packaging process, allowing for faster throughput while maintaining high standards of quality control. Additionally, fill and seal machines contribute to improved product freshness and shelf life by reducing exposure to contaminants during packaging.

Versatility is another key feature of fill and seal machines, as they can accommodate a variety of packaging needs, making them suitable for different products and industries. This flexibility ensures that businesses can adapt to changing market demands without incurring excessive costs. Furthermore, the use of fill and seal machines is cost-effective, as they help reduce material waste and optimize resource usage. Overall, these machines are essential for achieving consistency in packaging, making them an invaluable asset for any packaging operation.

Related Posts

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

-

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

-

What is a Horizontal Packaging Machine and How Does It Work?

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

Why Overwrapping Machines Are Essential for Efficient Packaging Solutions

-

Top 10 Tips for Choosing the Best Overwrapping Machines for Your Business

Products

Links

© Copyright 2025 | All Rights Reserved