Experience & Vision

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

As the demand for efficient and streamlined packaging solutions continues to rise, the role of High-speed Form-Fill-Seal (HFFS) machines has become increasingly pivotal in the global food and beverage, pharmaceutical, and personal care industries. According to a recent market analysis report by Mordor Intelligence, the global HFFS machine market is projected to grow at a Compound Annual Growth Rate (CAGR) of over 6% from 2022 to 2027. This growth is driven by the necessity for automation in packaging processes, which enhances productivity while minimizing operational costs.

HFFS machines offer a myriad of features that cater to modern manufacturing needs, including versatile packaging formats, advanced control systems, and enhanced reliability. With the rising focus on sustainability, many HFFS systems are designed to handle recyclable and biodegradable materials, aligning with industry trends towards environmentally friendly packaging. Additionally, the incorporation of smart technology enables real-time monitoring and predictive maintenance, thereby reducing downtime and improving overall efficiency in production lines.

In this landscape, understanding the critical features and benefits of HFFS machines is essential for manufacturers aiming to stay competitive. As we delve deeper into the top HFFS machines set to make a mark in 2025, we will explore not only their technological advancements but also how these innovations can significantly impact operational efficiencies and cost savings in packaging processes.

Key Features of 2025 Top HFFS Machines

The 2025 top Horizontal Form-Fill-Seal (HFFS) machines are revolutionizing the packaging industry with their innovative features aimed at efficiency and sustainability. One of the key features of these machines is their enhanced automation capabilities. With the integration of advanced sensors and AI-driven algorithms, these HFFS machines can optimize the filling and sealing processes in real-time, reducing downtime and minimizing waste. This automation not only streamlines operations but also ensures consistent quality in packaging, which is critical for maintaining product integrity.

Another significant benefit of the latest HFFS machines is their versatility in handling a wide range of materials. Manufacturers can now package both flexible and rigid substrates, accommodating various product types and sizes. This adaptability is coupled with energy-efficient operation, allowing companies to reduce their carbon footprint. Additionally, the machines are designed for easy maintenance, featuring modular components that can be quickly replaced or serviced, enhancing overall productivity while minimizing operational disruptions. These advancements position the 2025 HFFS machines as essential tools for businesses striving to meet both market demands and environmental responsibilities.

Advantages of High-Speed HFFS Machines in Packaging

High-speed Horizontal Form-Fill-Seal (HFFS) machines have revolutionized the packaging industry by enhancing operational efficiency and boosting production rates. These machines offer significant advantages, particularly in areas where speed and adaptability are critical. One of the primary benefits of high-speed HFFS machines is their ability to streamline the packaging process, allowing manufacturers to increase output without compromising on quality. This is achieved through advanced automation and precise control mechanisms, which ensure that each package is filled and sealed perfectly at higher velocities.

In addition to speed, high-speed HFFS machines provide flexibility that is essential for modern packaging needs. They can handle a wide range of materials and package formats, enabling manufacturers to switch quickly between product lines without extensive downtime. This adaptability not only improves responsiveness to market demands but also enhances the overall efficiency of production workflows. Furthermore, the integration of sophisticated technology in these machines, such as smart sensors and real-time monitoring systems, allows for better quality control and reduced material waste, further contributing to sustainability efforts in the packaging sector.

Comparison of Leading HFFS Machines on the Market

When exploring the world of Horizontal Form Fill Seal (HFFS) machines, understanding their features and benefits is crucial for making informed decisions. The market is saturated with various HFFS machines, each offering unique capabilities and efficiencies. Leading models typically boast key features such as high-speed operation, versatility in packaging materials, and advanced automation. These features enhance productivity and ensure consistent packaging quality, which is vital for businesses aiming to streamline their operations.

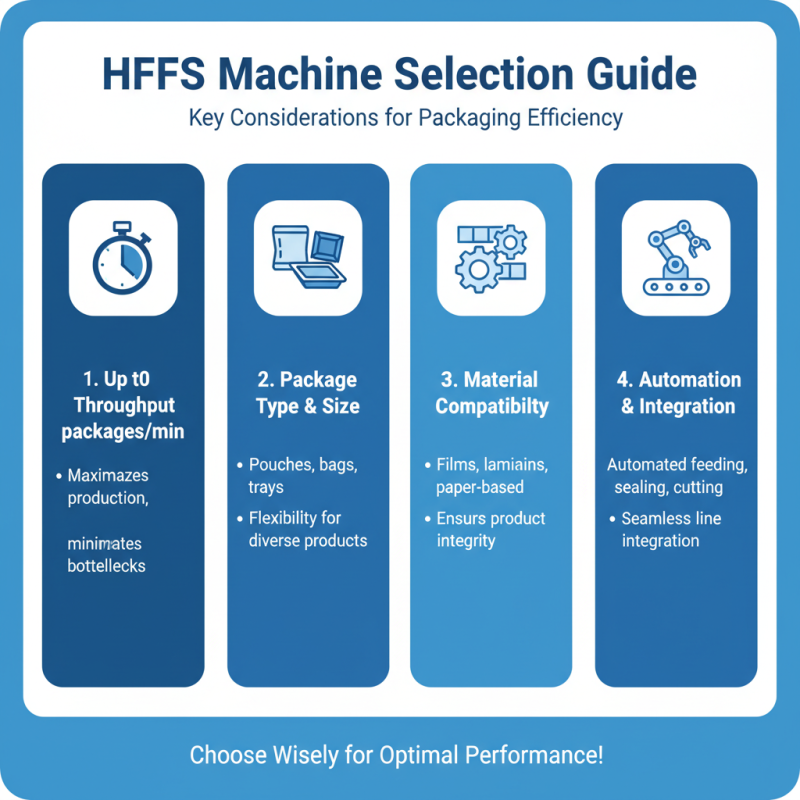

Tips for selecting the right HFFS machine include assessing your specific production needs and considering the types of products you will be packaging. It is also important to evaluate the machine's ease of use and maintenance requirements to minimize downtime. Additionally, look for features like adjustable sealing mechanisms and software compatibility that allow for future upgrades as your production demands evolve.

When comparing leading HFFS machines, pay attention to their energy efficiency and integrated technology, which can significantly reduce operational costs in the long run. Machines equipped with sophisticated monitoring systems can enhance quality control by providing real-time feedback on the packaging process. By prioritizing these aspects, you'll be well-positioned to choose an HFFS machine that not only meets your current needs but also adapts to future challenges in the packaging industry.

2025 Top HFFS Machines: Key Features and Benefits

Innovative Technologies in 2025 HFFS Machine Design

The design of horizontal form-fill-seal (HFFS) machines in 2025 is set to incorporate several innovative technologies that enhance efficiency and productivity in various packaging applications. One key feature is the integration of advanced automation solutions, which streamline operations from material handling to product packaging. Such automation minimizes manual intervention, reducing labor costs and the likelihood of errors. Additionally, intelligent sensors embedded within these machines provide real-time monitoring, allowing for quick adjustments to enhance performance and maintain quality standards.

Another noteworthy trend in HFFS design is the focus on sustainability. Manufacturers are increasingly adopting eco-friendly materials and energy-efficient processes that minimize waste and reduce carbon footprints. This shift not only meets the growing consumer demand for sustainable packaging solutions but also helps businesses align with global environmental standards.

Tip: When evaluating HFFS machines, consider not only their technical specifications but also how they align with your sustainability goals. Investing in machines that utilize recyclable materials and have energy-saving features can lead to long-term savings and a positive brand image.

Furthermore, the adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence, is revolutionizing the way HFFS machines operate. These technologies facilitate predictive maintenance, helping businesses to avoid costly downtimes and improve overall equipment effectiveness. By leveraging data analytics, manufacturers can also gain insights into production processes, allowing for continuous improvement and greater flexibility in response to market demand.

Tip: To maximize the benefits of IoT in your HFFS operations, ensure that your team is trained in data analysis and machinery maintenance, as a knowledgeable team can significantly enhance machine performance and longevity.

2025 Top HFFS Machines: Key Features and Benefits You Need to Know

| Machine Model | Speed (Packages/Min) | Film Type | Key Feature | Benefit |

|---|---|---|---|---|

| Model A | 150 | Polyethylene | Automatic Film Feeding | Increased Efficiency |

| Model B | 130 | BOPP | Energy Efficient Design | Lower Operating Costs |

| Model C | 175 | PVC | Multi-Layer Packaging | Longer Shelf Life |

| Model D | 120 | PLA | Eco-Friendly Options | Sustainability |

Considerations for Selecting the Right HFFS Machine

When selecting the right Horizontal Form Fill Seal (HFFS) machine for your packaging needs, several key considerations can significantly impact operational efficiency and product integrity. Notably, industry reports emphasize the importance of throughput rates, with top-performing machines achieving speeds of up to 300 packages per minute. This high throughput is crucial for businesses aiming to meet increasing market demands while minimizing production bottlenecks.

Another critical factor to consider is the machine's versatility and compatibility with various film types. Recent studies have highlighted that flexible packaging is projected to grow by 4.3% annually, underscoring the need for HFFS machines capable of handling a diverse range of materials, such as polyethylene and biodegradable options. This adaptability not only expands your product offerings but also aligns with sustainability goals increasingly prioritized by consumers.

Additionally, ease of maintenance and operational support are vital aspects that should influence your decision. A report from the Packaging Machinery Manufacturers Institute indicates that efficient maintenance practices can reduce downtime by up to 20%. This efficiency not only enhances productivity but also extends the lifespan of the machine, providing long-term cost benefits. Therefore, investing in an HFFS machine that offers robust support and streamlined maintenance protocols can lead to significant advantages in your packaging operations.

Products

Links

© Copyright 2025 | All Rights Reserved