Experience & Vision

2025 Guide: How to Choose the Right Packaging Machinery Equipment for Your Business

In the rapidly evolving landscape of modern industries, the role of packaging machinery equipment has become increasingly pivotal. As businesses strive to enhance efficiency and reduce operational costs, investment in the right packaging solutions can significantly influence a company’s bottom line. According to a report by Smithers Pira, the global packaging machinery market is projected to grow to $56 billion by 2024, driven by rising demand for automation and sustainability in packaging processes. This growth highlights the necessity for businesses to carefully evaluate their packaging needs.

Choosing the right packaging machinery equipment is not merely a matter of selecting a machine; it involves analyzing production capacities, material compatibilities, and technological advancements. In 2021, it was noted that automated packaging solutions can reduce labor costs by up to 30%, making it an attractive option for businesses aiming for scalability. Furthermore, with consumers increasingly preferring eco-friendly packaging, investing in machinery that accommodate sustainable materials can set companies apart in a crowded market. Thus, understanding the specific requirements and anticipating future trends are crucial steps in making informed procurement decisions that can lead to increased efficiency and competitive advantage in the packaging industry.

Understanding Your Packaging Needs and Objectives

When selecting the right packaging machinery for your business, it's essential to understand your specific packaging needs and objectives. According to a recent industry report by Smithers Pira, the global market for packaging machinery is projected to reach $50 billion by 2025, highlighting the growing importance of innovative and efficient packaging solutions. Businesses must assess various factors, such as product type, volume, and shelf-life requirements when determining their packaging needs. A tailored approach ensures that machinery not only meets current demands but also accommodates future growth.

To streamline the selection process, consider conducting a thorough analysis of your production line and workflow. This includes evaluating the materials you use, the size of your products, and any legal or regulatory requirements specific to your industry. Investing in machinery that enhances productivity while ensuring compliance will significantly contribute to your bottom line.

**Tips**:

1. Evaluate the total cost of ownership (TCO) of the machinery, factoring in maintenance, operation costs, and potential downtime.

2. Engage with a machinery consultant to identify technology that aligns with your business objectives, facilitating smoother integration into existing processes.

3. Don't overlook the importance of scalability in your equipment choice, ensuring it can adapt to increases in demand without significant additional investment.

Exploring Different Types of Packaging Machinery Available

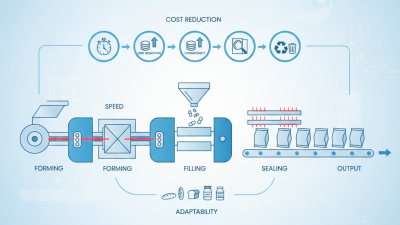

When choosing the right packaging machinery for your business, understanding the various types available is crucial. The packaging machinery market is projected to reach $50 billion by 2025, driven by the increasing demand for efficiency and sustainability in packaging processes. Companies can explore several categories of machinery, including filling machines, labeling machines, and palletizers, each with distinct functions tailored to specific packaging needs. For instance, according to a recent report from Smithers Pira, filling machines are essential in sectors such as food and beverage, where ensuring product integrity and maintaining hygiene standards are paramount.

In addition to filling machines, labeling machines play a vital role in branding and compliance. As highlighted by the Freedonia Group, the global labeling equipment market is expected to grow significantly, fueled by the demand for custom labeling options that enhance product visibility and consumer engagement. Furthermore, palletizers automate the stacking of packaged products, thus enhancing warehouse efficiency and reducing labor costs. The right combination of these machinery types not only improves operational efficiency but also supports scalability and responsiveness to market trends. With the right insights and careful selection, businesses can optimize their packaging processes to meet both current and future demands.

2025 Guide: How to Choose the Right Packaging Machinery Equipment for Your Business

| Packaging Machinery Type | Best For | Advantages | Typical Applications |

|---|---|---|---|

| Fillers | Liquid products like beverages, oils, and sauces | High accuracy, efficiency in high-volume production | Bottling, pouch filling, jar filling |

| Labelers | All types of bottles and containers | Improved product presentation, brand visibility | Bottles, boxes, jars, cans |

| Cartoners | Pharmaceuticals, cosmetics, food products | Speed and automation, reduces labor costs | Cartoning bottles, boxes, pouches |

| Seal Machines | Food, pharmaceuticals, consumer goods | Ensures product integrity, prevents leakage | Sealing pouches, bags, containers |

| Wrapping Machines | Boxes and products of various shapes | Efficient secondary packaging, product protection | Shrink wrapping, stretch wrapping |

Evaluating Key Features and Specifications of Equipment

When selecting packaging machinery for your business, evaluating key features and specifications is crucial to ensure that the equipment meets your operational needs. Start by identifying the type of products you'll be packaging, as this will dictate the size, speed, and capabilities of the machinery required. Look for machines that offer versatility, allowing for adjustments in size and packaging style to accommodate different products as your business evolves.

Tip: Consider the ease of use and maintenance of the equipment. Machines with user-friendly interfaces and straightforward setups can significantly reduce training time and operational errors. Also, check the availability of spare parts and support services, as reliable after-sales service can mitigate downtime during critical production periods.

Another important aspect is the scalability of the equipment. As your business grows, you may need to ramp up production. Choosing machinery that can be easily upgraded or expanded will save you from having to invest in new equipment too soon. Look for features such as modular designs and adaptable technology that can keep pace with your increasing demands without requiring a complete overhaul of your existing setup.

Tip: Always factor in energy efficiency and overall cost-effectiveness in your evaluations. Investing in machinery that minimizes energy consumption not only supports sustainable practices but also helps in reducing operational costs over time, aligning with your long-term business goals.

Assessing Budget and Financial Considerations for Purchasing

When considering the purchase of packaging machinery equipment for your business, understanding the budget and financial implications is crucial. According to a report by Smithers Pira, the global market for packaging machinery was valued at approximately $45 billion in 2020, with projections to reach over $60 billion by 2025. This steady growth indicates the importance of investing in efficient and reliable machinery to optimize production and reduce long-term operational costs.

A well-defined budget should not only account for the initial acquisition cost but also consider factors such as maintenance, operational efficiency, and potential downtime. Industry data shows that businesses can save up to 20% in operational costs by investing in state-of-the-art technology that enhances productivity and minimizes waste. Thus, it is essential to evaluate the return on investment (ROI) for different machinery options and forecast how these investments will impact your bottom line over time. Engaging in thorough financial planning and exploring various financing options, such as leasing or partnering with equipment suppliers, can provide flexibility and mitigate financial risks.

Maintenance and Support: Ensuring Longevity of Packaging Solutions

When investing in packaging machinery, businesses often focus on initial costs and specifications, but neglecting maintenance and support can lead to increased downtime and expenses in the long run. According to a recent industry report, nearly 30% of machinery failures can be attributed to inadequate maintenance practices. Implementing a comprehensive maintenance strategy not only enhances the longevity of equipment but also improves operational efficiency. Regular checks and timely repairs ensure that packaging solutions perform optimally, ultimately safeguarding your investment.

To ensure the longevity of your packaging machinery, consider these tips: First, schedule routine maintenance checks to identify potential issues before they escalate into costly repairs. Second, train your staff on the proper use and care of the equipment; studies indicate that improper operation is a significant contributor to machinery breakdowns. Third, establish a relationship with a reliable support service that can provide quick responses for technical assistance, ensuring minimal disruption to your operations.

Maintaining a focus on support services can also enhance your packaging line's adaptability to new technologies. With changing consumer demands and innovations in packaging materials, having a partner that understands your equipment's capabilities and limitations can guide your business in making informed upgrades or adjustments. By prioritizing maintenance and support, businesses can not only extend the life of their packaging solutions but also sustain their competitive edge in the evolving market landscape.

2025 Packaging Machinery Maintenance Trends

Related Posts

-

What is a Form Fill Packaging Machine and How Does It Work for Your Business

-

Top 10 Cartoning Machines for Efficient Packaging Solutions

-

Top 5 Benefits of Using Fill and Seal Machines for Efficient Packaging

-

What is Packaging Equipment and How to Choose the Right One for Your Needs

-

What is a Filling Machine and How Does it Work in Various Industries

-

How to Choose the Right Form Fill Packaging Machine for Your Business Needs

Products

Links

© Copyright 2025 | All Rights Reserved